CORN EAR MOLDS: Basic Questions and Answers (PP1451, Reviewed Jan. 2020)

Corn ear molds may develop because of wet conditions that delay corn dry-down and grain harvest. Corn ear molds are of concern because of their potential to produce mycotoxins, which may affect livestock feeding value and animal health.

Where may I send corn ears to have the mold fungi identified?

Send corn ears or kernels to the NDSU Plant Diagnostic Laboratory for identification of molds. Contact the lab at www.ag.ndsu.edu/pdl or

701-231-7854 for the current price of the testing.

The courier (FedEx, UPS, etc.) address is:

NDSU Plant Diagnostic Laboratory

Dept. of Plant Pathology

306 Walster Hall, NDSU

Fargo, ND 58102

The U.S. Postal Service address for regular mail is:

NDSU Plant Diagnostic Laboratory

NDSU Dept. 7660

P.O. Box 6050

Fargo, ND 58108

Where may I send corn ears for mycotoxin analysis?

Corn with visible mold does not necessarily have mycotoxins present. The presence of mycotoxins can be determined only by laboratory testing. The NDSU Veterinary Diagnostic Lab can complete mycotoxin analyses on corn ears, grains and silage. A full mycotoxin screen is $150 per sample plus a $10 fee to set up an account regardless of the number of samples being submitted. Contact the lab at www.vdl.ndsu.edu or 701-231-8307.

The courier address for submitted samples is:

NDSU Veterinary Diagnostic Laboratory

4035 19th Ave. N.

Fargo, ND 58102

The U.S. Postal Service address for regular mail is:

NDSU Veterinary Diagnostic Laboratory

Dept. 7691

P.O. Box 6050

Fargo, ND 58108-6050

Various private labs in the region also may be able to test corn for molds and mycotoxins.

What are the common ear molds in North Dakota?

Based on prior years with wet fall corn, the most common mold generally observed is Cladosporium. This fungus causes a dark green to black mold growth frequently seen on the kernel surface, between kernels or into the cob. (See photos above by Kasia Kinzer, former NDSU plant diagnostician.) This fungus is not known to produce mycotoxins of concern.

Other ear rots and molds that may occur, depending on temperature and moisture content, include:

- Gibberella and Fusarium ear rots — often associated with white to pink to red discolorations, and potentially producing mycotoxins such as vomitoxin, zearalenone and fumonisin. Can be common in North Dakota.

- Penicillium — blue-green mold growth potentially producing ochratoxin

- Diplodia — white to gray mold growth not known to produce mycotoxins. Not known to occur readily in North Dakota.

- Aspergillus — green mold growth potentially producing aflatoxin, but generally in hot, dry years

Some mold growth may be superficial and not infect the intact kernels.

Can mold spores cause respiratory problems?

Abundant mold spores can cause respiratory problems in sensitive livestock and in humans. Farmers and grain handlers should wear respiratory protection, such as an N-95 rated mask, to minimize exposure to mold spores during grain handling.

What are the effects of mycotoxins on livestock?

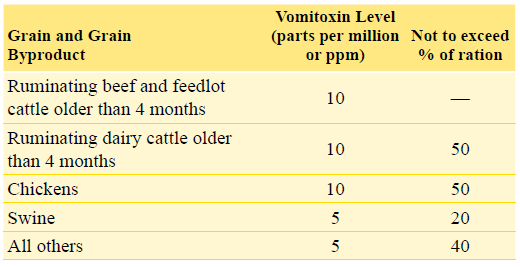

The U.S. Food and Drug Administration (FDA) has issued advisory levels for various mycotoxins in grain. If mycotoxins are detected, livestock producers should be aware of these advisory levels. For example, the following table provides information on FDA advisory levels for vomitoxin in animal feeds.

What effects can molds have on the marketing or price received for corn?

Elevators, ethanol plants and feed mills apply price discounts for moldy corn and various mycotoxins. Price discounts can vary depending on the buyer, the mold or mycotoxin levels, and the intended use for the corn.

High levels of mold or mycotoxins may result in the buyer refusing to take delivery. Growers need to check with alternative buyers to determine the base price for the corn, as well as any price discounts that may apply.

What effect do the molds have on ethanol plant purchasing of corn?

The guidelines for moldy grain can vary among ethanol plants. One ethanol plant provided the following guidelines: Corn with moisture above 15% will be discounted. The plant also will do a visual inspection for damage before accepting corn. If damage (including broken kernels and moldy kernels) is above 10%, the ethanol plant will not accept the corn.

Mycotoxins are not destroyed during ethanol processing; they become concentrated about three-fold in the dried distillers grains (DDGS). If mycotoxin levels in the corn and DDGS become a concern, restrictions on moldy corn could be strengthened.

Do I need to contact my insurance agent prior to harvest if I see corn ear molds in my fields?

Yes. Federal Crop Insurance Corporation policies cover losses due to substances that injure human or animal health, such as certain molds and mycotoxins. However, take samples before the crop enters on-farm or commercial storage. Test to determine the source and level of damage. Growers need to contact their insurance agent to find out the proper collection and reporting requirements.

If moldy corn is dried appropriately, do molds and mycotoxins continue to develop?

No. Proper drying (to less than 15% moisture content, or MC, for winter storage and 13% MC for summer storage) and proper cooling and storage management will not allow further development of corn ear molds or mycotoxins. However, any mycotoxins that formed prior to drying will remain in the corn and will not be destroyed during high-temperature drying or storage.

What are appropriate harvesting and storing practices to reduce the risk of further mold and mycotoxins development?

Mold growth in standing corn will continue until temperatures drop below about 40 F or corn moisture is reduced to about 20%. Use natural air and low temperatures for spring drying, but initial corn moisture should be less than 20% and the airflow rate should be at least 1 cubic foot per minute per bushel.

Corn with damaged kernels should be marketed or fed to animals by early summer because of its shorter storage life. Incorporate a screen cleaner into the handling system to remove fine materials before the corn is placed in the bin. Learn more about corn drying and storage at www.ag.ndsu.edu/graindrying.

What are the effects of ensiling on mold growth and mycotoxin production?

Late mold growth on ears may have little impact on traditional corn silage methods. Producers with corn silage who have concerns about mycotoxins should have the silage tested for mycotoxins prior to feeding. Harvesting the corn as high-moisture grain and storing the grain in a bunker, upright or other silo structure also should slow or arrest mold growth in the corn, provided anaerobic conditions and a low pH environment are maintained. Feed corn stored in this manner (fermented) only to ruminant livestock.

This publication was authored in 2009 by the following NDSU faculty and staff: Ken Hellevang, Kasia Kinzer, Greg Lardy, Marcia McMullen, Michelle Mostrom, Frayne Olson, Scott Pryor, Joel Ransom and J.W. Schroeder in cooperation with the North Dakota Corn Growers Association.