Home Envelope: an energy guide to help you keep the outside out and the inside in (AE1616, Reviewed Feb. 2019)

Availability: Web only

insulation • air-sealing • caulking • weather-stripping • ice dams • basements • windows • doors ...and much more!

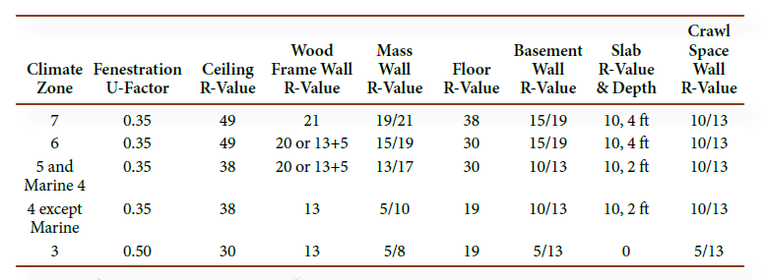

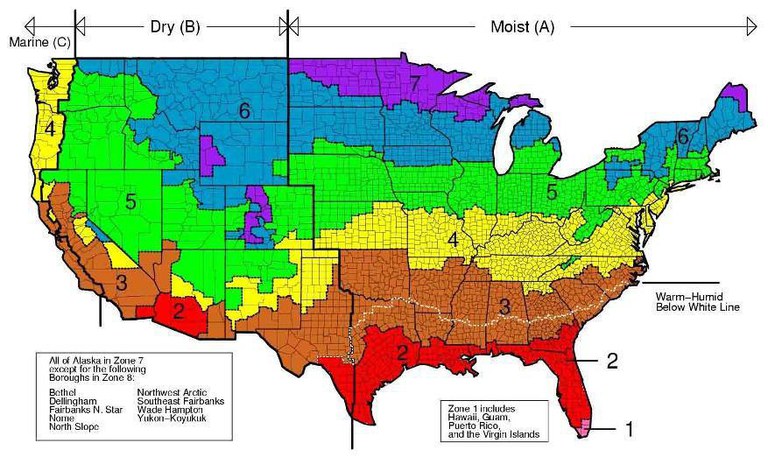

Climate Zone Recommendations

The International Code Council provides minimum recommendations for insulation values of various building components based on climate zones. These U- and R-values are provided below.

15/19 means R-15 continuous insulated sheathing or R-19 cavity insulation.

13+5 means R-13 cavity insulation plus R-5 insulated sheathing.

Saving Energy Makes Good Sense

How, when, and in what form we use energy has a dramatic effect on our lives, our bank accounts, and our environment. Using energy wisely makes sense and is a goal that we all could share.

The average family spends a significant amount of money on energy, but we can dramatically reduce these costs — up to 30 percent, according to the U.S. Department of Energy — by making some simple energy-saving improvements to our homes. In addition to saving money on utility bills, we can protect our homes from moisture damage year-round, reduce problems caused by ice dams on the roof during the winter, significantly cut summer cooling costs, extend the life of houses, and sometimes increase resale values. Furthermore, reductions in energy use also reduce environmental effects, including lowering contributions of carbon dioxide and other greenhouse gases.

Homes are no longer simple

When many of our homes were built, there was little concern about energy conservation and efficiency, therefore little attention was given to things like insulation and air leakage. Energy was cheap and construction materials and techniques were sufficient for the time.

Over the past several decades our homes (and the things within them) have become increasingly complex. Rising energy costs, along with environmental and other concerns, have increased awareness and driven research into the operations of buildings. The effects of the interactions of structural systems, weatherization components, mechanical equipment, and electrical devices in today’s homes are the subject of an entire field of study: building science.

Saving energy benefits everyone

Depending on your home, you may see substantial reductions in your energy use through conservation and efficiency improvements. Even if the annual savings for your home are modest, however, they go on, year after year. Many energy improvements will save enough money to pay for the initial investment in just a few years — some even sooner!

Building science

The interactions of the various parts of buildings have become better understood in the past few decades. The efforts of manufacturers, designers, architects, engineers, researchers, and builders to create homes that operate safely, comfortably, and efficiently is known as building science.

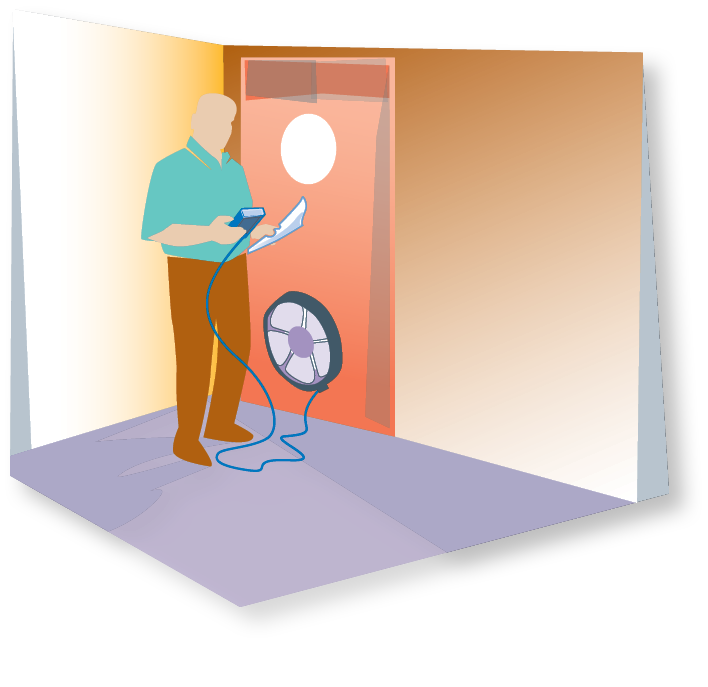

Energy audit tests

Includes a “blower door” test (above) to determine air leakage rates. Knowing how much and how quickly air is leaking through your home’s envelope can help prioritize energy- saving strategies.

What should be done first?

Many people assume that there is little they can do to significantly reduce their energy use and increase the efficiency of their homes. In reality, there are many things that typical residents can do themselves and many other things they can hire others to do.

Before you start on any large project, you should know what options you have and what the benefits may be. Today’s homes and their systems are much different than what was common 20, 30, or 50 years ago. The interactions between the various components of a house are more complicated, and the effects of systems not performing properly or being out of balance can be costly and sometimes dangerous. Having a home energy audit (sometimes called a home performance review) before embarking on your energy improvements or remodeling would be beneficial. This assessment of how your house is functioning can help you decide what needs fixing, what needs upgrading, and what needs replacement. Many people have a follow-up audit after work has been done to verify the estimated energy savings.

Energy audit: how your house works

A home energy auditor will assess the operation of your home by inspecting and measuring the performance of the building. Depending on the type of audit you receive, several things will be looked at:

- A visual inspection for attic, wall, crawlspace, foundation, basement, window, door, and roof problems.

- A review of energy bills to identify basic usage and identify opportunities for savings.

- A “blower door” test to determine air leakage rates.

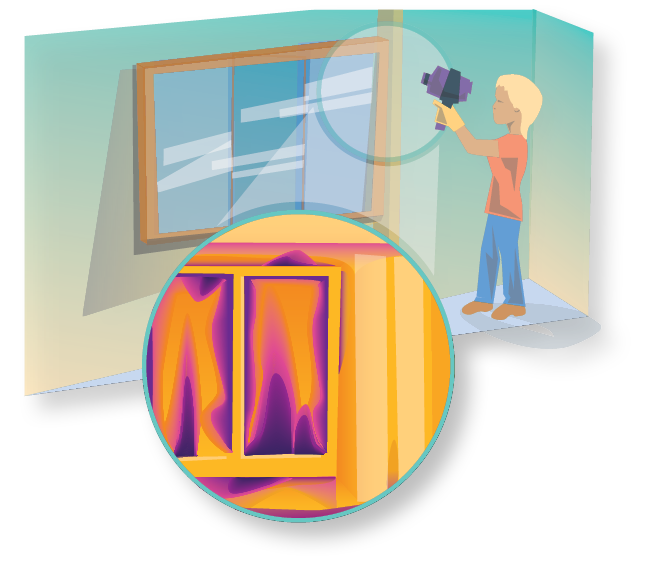

- Infrared scans of walls, attic, and foundation to assess insulation levels and locate possible air leak sources.

- Efficiency and safety testing for combustion appliances (like furnaces, boilers, gas fireplaces, and water heaters) to ensure they are operating properly and not contributing to indoor air concerns.

When should you get an energy audit?

Most homes—even recently built ones—can benefit from an analysis of the operation and interactions of the various systems and equipment. There are times when having a professional diagnosis can solve complicated problems while saving time, energy, and money. Consider an energy audit before:

- Replacing equipment such as a furnace, boiler, water heater, ventilator, or air conditioner. Finding and addressing air leakage, insulation, and other issues can help to correctly size new appliances and ensure they will work as efficiently as possible.

- Replacing windows, doors, or siding. Properly installed, these improvements can make your house much tighter, which can change the fresh air requirements for some combustion appliances or for the occupants.

- Investing in major remodeling or additions. Knowing the current operation of the home can help determine choices about designs, methods, or equipment options. In addition, a pre- and post-construction audit (with testing) can be used to verify energy performance improvements.

- Problem-solving systemic or complex concerns, such as excess moisture (including condensation, mold, mildew, or leakage), uneven heating or cooling, drafts, ice dams, or high energy bills.

How much does an energy audit cost?

Home energy audits range in cost from $35 to several hundred dollars, depending on the level of detail and the types of tests offered.

Contact your gas or electric utility to arrange for a basic energy audit. More comprehensive audits (for new construction or major remodeling) are available from private contractors specializing in comprehensive home performance reviews.

Energy audit tests

Can include scans from infrared cameras (below) to pinpoint voids in insulation, air leaks, and moisture problems. Knowing where the leaks are makes it easier to seal and make necessary repairs—and improves the returns on other energy investments you make.

How hard is it to make energy improvements?

If you have some basic tools and are comfortable with making repairs and improvements to your house, you can handle some of the projects suggested in this booklet and make the most of your energy-improvement budget. Be sure to check with your local municipality for permits and inspections.

However, don’t hesitate to call a professional for help if you’d rather not do the work yourself; even with paying to have someone else do the work, the dollars gained through energy savings in upcoming years will be worth the expense. Be sure to check out the “Resources” section at the end of this guide to get tips on hiring contractors.

How do I pay for it?

Although many energy-efficiency projects (caulking windows, weather-stripping exterior doors, or insulating water pipes) will cost just a few dollars, others (insulating exterior walls, air-sealing an attic, replacing a furnace, or adding storm windows) may cost considerably more.

Many utility companies offer incentives on larger projects (furnace replacement, attic insulation, new refrigerator) by giving you a discount on energy bills or sending you a rebate check when the work is completed. Other utilities offer free or discounted services or products (like low-flow shower heads, CFL bulbs, or energy audits). Contact your local energy utility or visit dsireusa.org for details.

Community nonprofits and neighborhood organizations offer a variety of services and programs, including energy audits, energy education, free or discounted products, and financing. Contact your city or municipality to learn what is available in your area.

Your bank may be able to help, too. Ask about a low-interest loan designed specifically to cover the cost of your energy-saving projects, or consider a home-improvement loan to fund them. Some banks offer energy efficiency mortgages, which take into account the reduced energy bills when improvements are made to homes.

Also, be sure to look into the availability of government-sponsored assistance. Some residents may be eligible for aid from the state Weatherization Assistance Program or Low Income Home Energy Assistance Program. Applications can be made through local community action agencies; go to for eligibility requirements, application forms, and contact information.

Finally, for the latest information on tax incentives, rebates, or grant programs from federal, state, or local governments, check out their websites. It is important to find out the specifics (qualifying products, installation requirements, site analysis, inspections, etc.) before purchasing products or services. Some programs require approved applications or specific products or procedures in order to qualify for the funding. Not meeting the requirements may jeopardize your incentive, rebate, or grant.

The Envelope of a Home

Simply speaking, the materials of a house that separate the outside from the inside are considered the home’s envelope. It is the barrier that keeps us from experiencing the extremes of the outside environment and keeps the inside of our home comfortable, dry, and energy efficient.

The home’s envelope includes windows, doors, walls, ceilings, and foundations. Each of these components consist of several elements that go together to create the structure. So, for instance, a wall section may consist of the interior paint, the drywall, the framing lumber, the air barrier and vapor sealing, the insulation, the exterior sheathing, the siding, and the exterior paint. Well-designed components work together to make the envelope as tight as possible.

Home tightening

Every home needs a certain amount of fresh air for the appliances that burn fuel, for getting rid of excess moisture for maintaining indoor air quality, and for reducing odors and stuffiness. When this air exchange is controlled, it’s called ventilation. When it seeps uncontrolled through cracks and holes in the envelope of our home, it is called air infiltration. Air that leaks through the ceiling, walls, foundation, and other areas are significant sources of heating and cooling losses in a home — up to one third in a typical house. Stopping air leaks is the best way to conserve energy, save money, and increase comfort. The bottom line: If you don’t tighten up your home first, other improvements (like windows, insulation, furnaces) may not be as effective.

Infiltration through air leaks can occur in three ways:

- Wind-driven infiltration happens during cold-weather months when the wind blows cold, dry air into a house through cracks and openings and forces warm air out. During warmer weather, the wind blows in warm, humid air, forcing cooler air out.

- Stack-effect infiltration takes place during the natural process of convection. As warm air rises and escapes through cracks at the top of the house, it pulls cold air into the lower areas.

- Negative air pressure infiltration starts when appliances use air for combustion or when ventilation fans are operated. Outdoor air enters through any available openings to equalize the pressure inside a home. This can be a problem if adequate fresh air for combustion has not been provided. It can lead to a potentially dangerous carbon monoxide risk as fresh air is pulled down chimneys or vents, interfering with

their proper operation.

Typically, air infiltration causes drafts and a chilly feeling near windows and doors and in basements. Adjusting your thermostat will not stop the drafts, but sealing hidden cracks and openings will. By stopping air leaks at their source, you’ll stay warmer in the winter and cooler in the summer, use less fuel, and reduce your utility bills.

Air infiltration

Outside air can enter your house through cracks in your foundation wall, siding, or around windows and doors. Inside (conditioned) air can escape around chimneys, vents, pipes, and wires that penetrate walls, ceilings, and attics.

Where do you start?

Fortunately, air infiltration is one of the easiest forms of energy loss to correct. The process requires only a careful inspection of your home and some inexpensive weather-stripping, caulking, and filler materials.

Most people know they should caulk and weather-strip around the exterior of their homes to protect it from the elements. However, it is equally important to protect your home from interior air leaks. Moist interior air can enter the walls and ceiling through cracks and holes, and condensation buildup in those locations can damage or destroy insulation, wiring, wood, or other building materials.

Look for air leaks

Before research and building science demonstrated the role air leaks play in energy loss, most people assumed that insulation was enough to stop heat flow through a building. Although insulation slows heat transfer, it is easily compromised by air flow, whether driven by outside wind conditions or convection currents within the building. The only way to stop this air movement — and the associated heat loss — is by eliminating the holes and pathways between the inside of the house and the outside.

The first step to tightening up your home’s envelope is performing a detailed inspection for air leaks. This should be part of every energy audit, and the auditor should be able to show you locations where air is leaking and needs to be sealed. A good rule of thumb is to seal the high air leaks first; in other words, start by plugging holes and leaks in the attic; then move to the exterior walls, and look for smaller leaks around doors, windows, and electrical switches and outlets; finally check out your basement.

Attic air leaks: more common than you’d guess

Most existing homes have many unsealed penetrations into the attic for wires, chimneys, vents, etc. Sealing will prevent heat loss and damage to building materials.

Hatches and doors to the attic

- Weather-strip the edges of the access hole and insulate the back of the attic hatch/door. Don’t forget doors to unheated knee wall areas.

Holes in attic floor

- Seal all openings around electrical wires, pipes, ducts, and vents with a good general-purpose caulk or spray foam. You may need to use a filler material for larger holes.

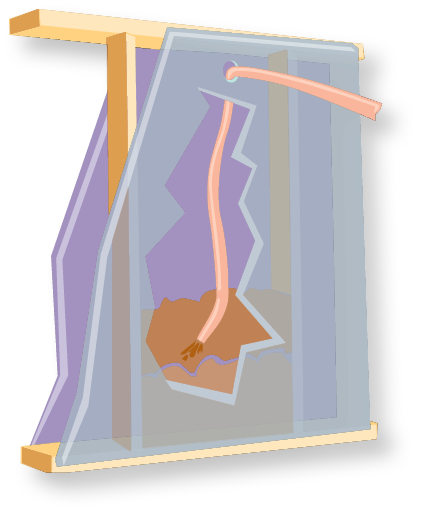

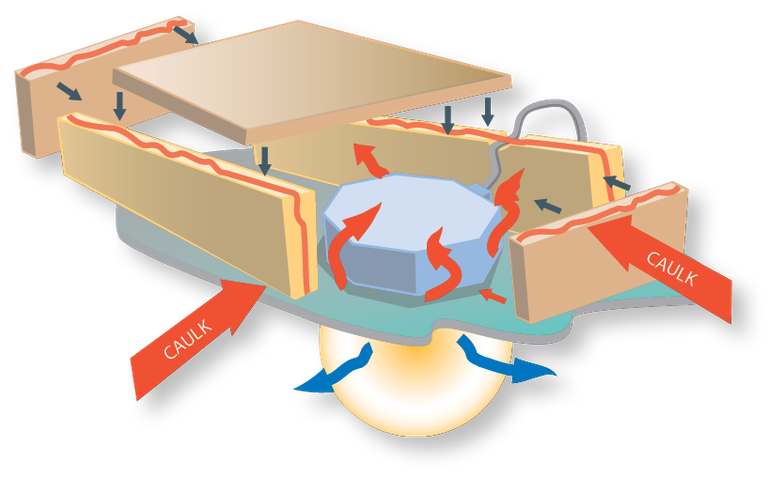

Recessed lights and bathroom fans

- These fixtures can poke into the attic insulation and create a pathway for air leaks. Caulk around them from below with flexible, high-temperature caulk. Install an airtight box sealed over the top of them in the attic, not only to stop air leakage but to reduce fire hazard from insulation lying against the fixture. See the illustration on the next page.

Chase for plumbing vent stack(s)

- This channel may run inside the walls of your home, from the basement to the attic, with openings at each floor where the lines branch off. If the chase isn’t much larger than the vent, seal with expanding foam. For larger chases, use drywall, wood, or rigid foam — and caulk or foam around all edges.

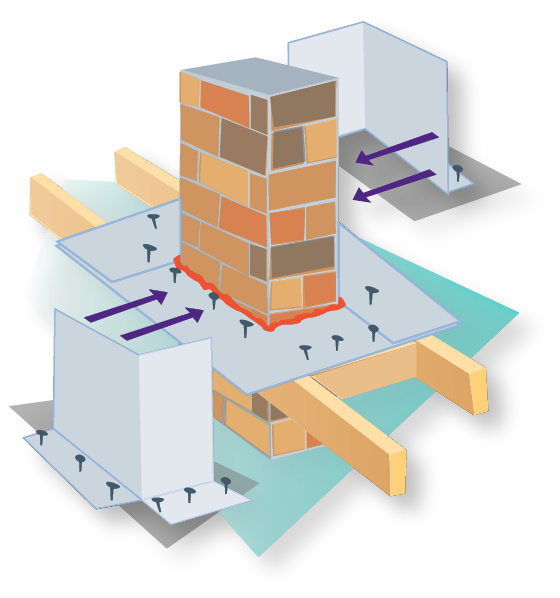

Fireplace chimney and furnace/water heater flues

- Close the gap between house framing and the chimney and vent flues with metal; seal with red fire-stop caulk.

Knee-wall storage drawers

- If storage drawers are recessed into the attic space, build an airtight, insulated box around the backside of the drawers. Don’t forget to seal all joints with caulk or sheathing tape.

Other holes

- Using the appropriate materials, seal all other holes between the heated space in your house and the attic.

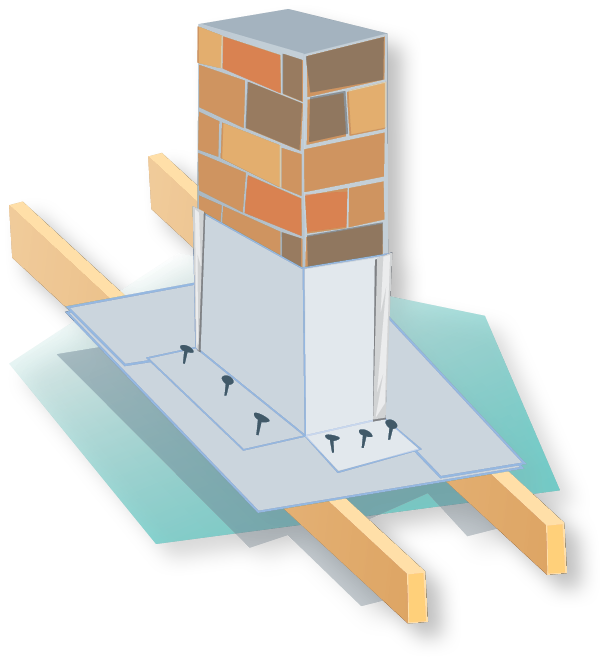

Chimney seal

1. Cut “L”-shaped pieces of aluminum or sheet metal to fit around chimney.

2. Seal gap between metal and chimney with red fire-stop caulk (above).

3. Install flashing and seal joints with metal foil tape. Install metal dams to hold insulation away from chimney at least one inch.

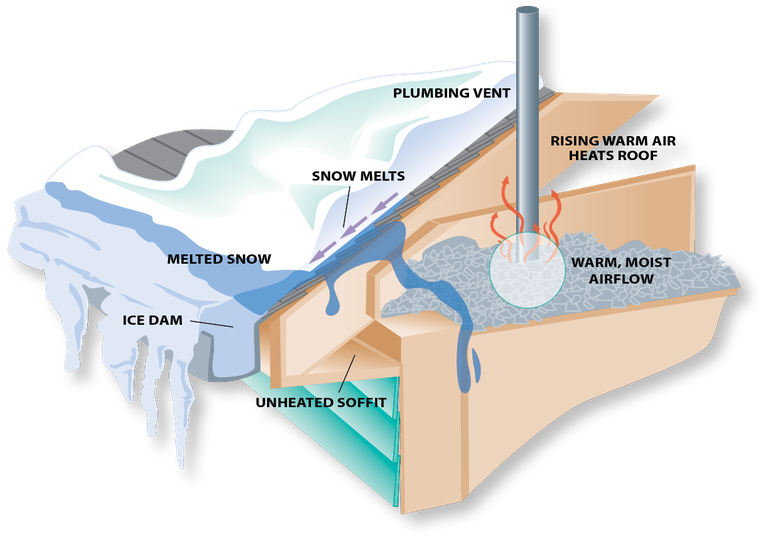

Attic air leaks = ice dams

Although many years ago thought of as a problem with just attic ventilation, ice dams are actually caused by the presence of warm air in the attic, combined with snow on the roof and the right weather conditions. Ice dams occur when heat gets into the attic and melts the underside of the snow on the roof. The melted snow then flows down the roof surface until it reaches a cold spot (such as the eaves or soffit) where it forms a frozen dam, behind which more snowmelt and ice pile up. The ice build-up can back up under the shingles, damaging them and allowing water to leak to the ceilings and walls below.

What NOT to do:

- Installing heating cables will shorten the life of your roof and cost you money to operate.

- Removing the ice with chippers, chemicals, or heat can damage shingles, gutters, and other building components.

- Adding roof vents alone may not eliminate ice dams, and may make the problems worse by pulling warm air from the home into the attic if adequate attic vents are not provided at the eave and ridge.

- Although additional insulation — especially higher density foam on the top plate of exterior walls — can reduce heat transfer to the roof deck, insulation alone is insufficient to eliminate ice dams if there is air leakage.

Damages insulation and more

Water vapor carried with the escaping warm air may condense, freeze, and build up in the insulation. When this water builds up, it can soak the insulation (wet insulation has little insulating value), cause plaster and paint to crack and peel, and lead to rot and other structural damage.

A primary source of ice dams is attic air leaks

Anywhere there is a penetration into the attic space (wires, plumbing vents, light fixtures, chimneys) there is the potential for air leaks. Even homes that are only a few years old may not be properly sealed. To avoid these types of problems and eliminate most ice dams, attic air leaks must be sealed with caulking or spray foam.

Knob and Tube Wiring

Seal wires and fixtures

- Electrical wires often enter attics through the tops of walls. Fill the hole around the wire with spray foam or caulking.

- Light fixtures that enter the attic space can be sealed with an airtight box made of wood or rigid foam to keep insulation off the fixture.

CAUTION: Turn off power to the entire circuit — not just the switch — and keep it off until the caulk or foam has cured completely!

CAUTION: If your wiring consists of old “knob and tube” style wires or wires that are worn or broken, they must be repaired or replaced prior to insulating and sealing!

What to do about attic air leaks

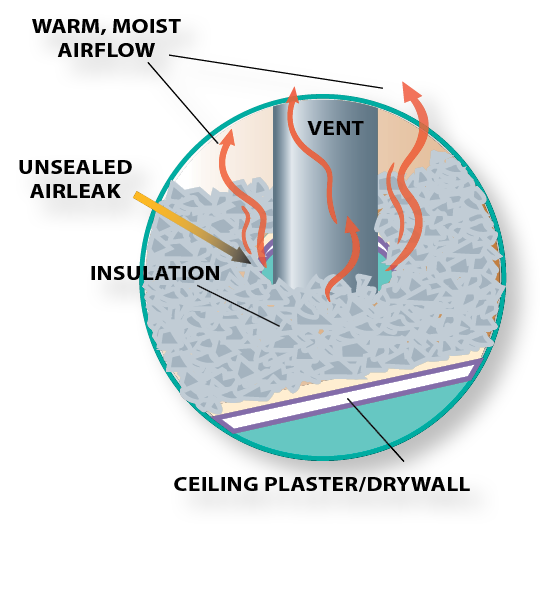

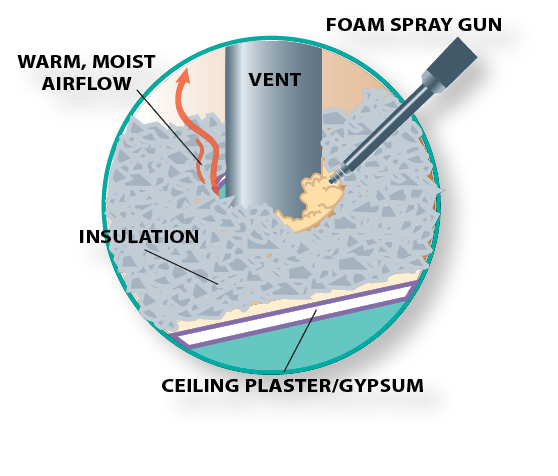

Warm, moist air leaking through holes around plumbing vents, electrical wires, chimneys, etc. leads to reduced performance of the insulation.

Foam spray or caulking can seal up the air leak, saving energy and reducing ice dams.

Basement air leaks: easy to seal if unfinished

Most basements have multiple air leakage locations. Because of the physics of the stack-effect (causing warm air to rise), basements are a common source of cooler air leaking in through cracks or penetrations in the foundation or unsealed joints where floor framing rests on the foundation wall. Air then rises through holes around chimneys, vents, wires, and plumbing into the rest of the house. Careful sealing will help to limit warm air entering the attic.

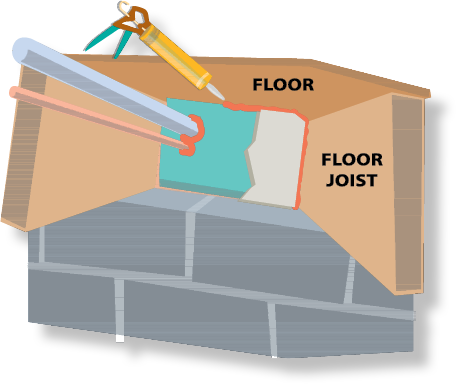

Sill plate and band or rim joist

- Caulk cracks between the sill plate and foundation wall using a masonry caulk, and fill cracks between the sill plate and band or rim joist. Then insulate the band/rim joist area by spraying with expandable foam or by cutting foam board insulation to fit and then caulking in place. Do not use fiberglass, as it does not stop air infiltration and because moisture from the basement can get between the fiberglass and the rim joist, leading to mold and mildew.

Chase for plumbing vent stack(s)

- Sealing the chase at the basement end, as well as the attic end, will reduce the flow of air to the other floors in the house.

Vent flues for furnace and water heater

- As in the attic, close the gap between framing and chimney/vent flues with metal; seal the edges with red fire-stop caulk. Flues made of PVC (plastic) piping can be sealed directly with spray foam or regular caulking.

Hatch or door to crawl space

- Weather-strip the edges and insulate the back of the hatch or door.

Openings through basement ceiling

- Seal with caulk or foam the hole where the bathtub drain comes down and other holes for plumbing or electrical wiring in the basement ceiling. You may need to use filler material for larger holes.

Basement windows

- Using a masonry caulk or spray foam, fill cracks where the frames of the windows are set into the walls. Windows that are not used for ventilation or as fire exits can be caulked shut permanently.

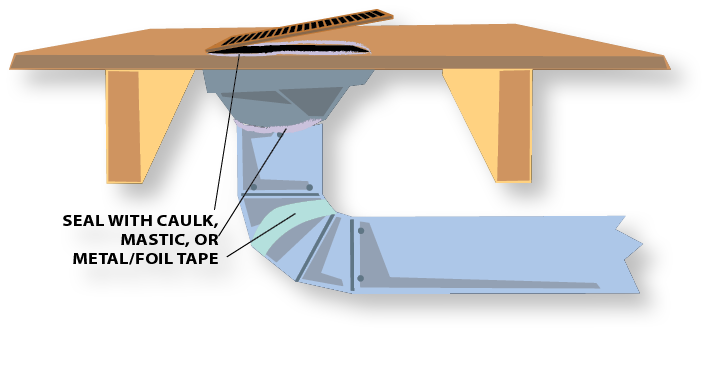

Ducts

- In homes with air ducts, there may be gaps where they pass through ceilings, floors, and walls. Caulk or foam where the metal duct and the ceiling, floor, or wall meet.

Other holes

- Seal cracks or holes in the foundation with caulk, foam, or the appropriate patching material. Don’t forget to check where the electrical, gas, water supply, telephone, and cable lines enter the house, and seal on the inside and outside.

DON’T SEAL COMBUSTION AIR SUPPLIES!

- Water heaters or furnaces may have a flexible duct that supplies fresh air for combustion. These must be kept open! A “J” loop near the duct end can reduce cold air in the basement.

Seal vents and ducts

Vents for dryers, exhaust fans, or high efficiency water heaters or furnaces that exit through foundation walls or rim joists should be caulked or foamed to prevent air leakage (above).

Furnace ducts that rise from basements through walls should be sealed where the metal meets the wood framing (below).

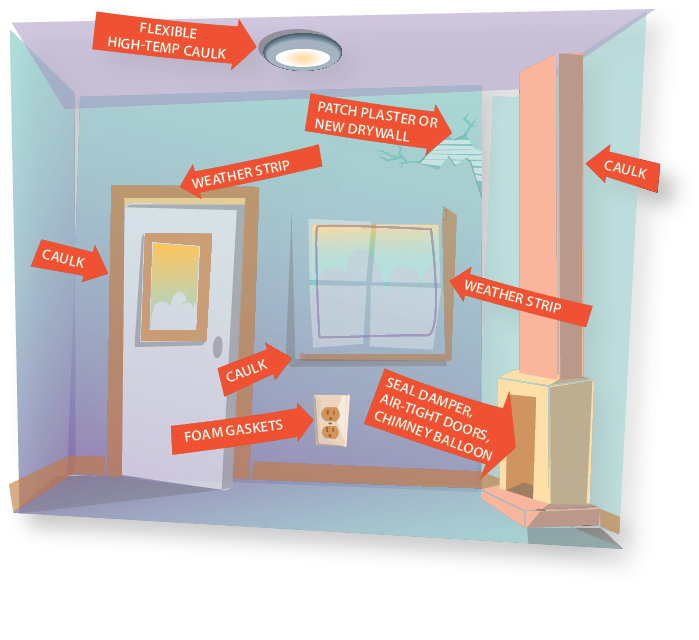

Living space air leaks: plug the holes around you

Air leaks in the occupied part of your home are the ones you are most likely to notice. The drafts of air infiltration can be felt around windows, doors, outlets, and fireplaces. The results of these air leaks can frequently be seen as condensation or frost build-ups on windowsills or the bottoms of doors.

Window and door frames, trim, and baseboards

- Carefully remove trim and caulk or foam the gap between the wall framing and the window or door jamb (no fiberglass, it doesn’t air-seal). If you are unsure how to properly remove and replace the trim, consider hiring it done. Use low-expansion foam around windows and doors.

- If you don’t want to remove the trim, you can caulk the edges of trim and baseboard where it joins walls and floors with an interior-grade caulk. Use a clear caulk for hardwood or tile floors and trim with natural wood finishes and paintable caulk for painted trim and carpeted floors. Note: caulk on wall/trim may be a challenge when repainting.

Missing plaster

- Exposed laths indicate a direct hole into wall and ceiling cavities. Repair with plaster or cover with new drywall.

Cracks in plaster and drywall

- Repair cracks using the appropriate patching material, and repaint.

Windows and doors

- Check the weather-stripping on all windows and doors, and repair or replace as necessary. Check the threshold on doors, and replace if worn or leaking air. Replace broken glass and reglaze or putty loose windowpanes. Caulk around moving parts of windows with nonpermanent caulk that can be removed easily. You can also install inexpensive window films (inside is best) to cut air leaks.

Electrical switches and outlets

- Install foam gaskets and child-safety plugs on all switches and outlets — even on interior walls. Although this may have a very small effect on heat loss from air infiltration, it can have a noticeable effect on comfort, by reducing drafts. Feeling a draft can lead to turning thermostats higher than necessary.

Other holes in exterior walls

- Caulk or foam around all ceiling fixtures, heat registers, medicine cabinets, bathtubs, kitchen cabinets, drains, and water pipes where they enter the wall in the kitchen and bath. Also seal any other holes in exterior walls.

Seal holes, cracks, leaks

Anything that penetrates your walls or ceilings is a potential location for an air leak. Gaps around windows, doors, fireplaces, electrical boxes — even cracks in plaster — can allow air to move between the inside and outside of your house. Seal them up with caulk, weather-stripping, or plaster. Foam gaskets on outlets and switches can increase comfort, avoiding unnecessary energy use.

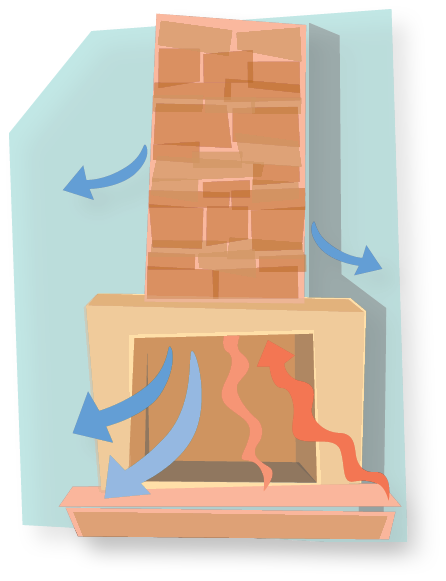

Fireplaces: waste more heat than they make?

A charming old fireplace may seem warm and cheery, but it likely loses more heat from your home than it gives off. Warm air in a home is sucked up the chimney and is replaced by cold air leaking into the house. Especially as the fire dies down, more heat is drawn up the chimney than is created by the fire — and the reduced rate of airflow can lead to backdrafting of flue gases and smoke into the living space.

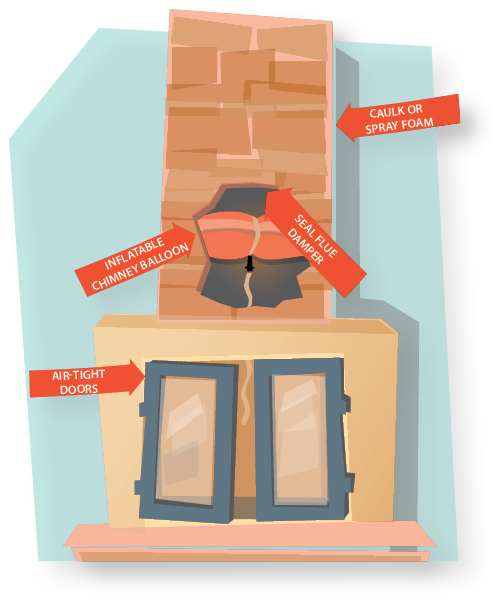

Follow these tips to improve the operation and safety of your fireplace and to reduce your energy losses:

- Improve the seal of the flue damper. To test the damper’s seal, close the flue, light a small piece of paper, and watch the smoke. If the smoke goes quickly up the flue, there’s an air leak. Seal around the damper assembly with refractory cement, but don’t seal the damper closed.

- Install tight-fitting glass doors or an airtight fireplace insert unit. Controlling the airflow in your fireplace improves combustion efficiency by 10 to 20 percent and reduces air leaks up the chimney. When there is no fire or embers, close all vents and dampers tightly.

- If you infrequently use the fireplace, install an inflatable “chimney balloon” in the flue of the chimney to reduce heat loss. These are available in several sizes and, if properly installed, can significantly reduce heat loss through the flue. Most have a quick-release handle, and many have a safety feature that will instantly deflate the balloon when a fire is started without removing the balloon.

- Many fireplaces and stoves have a source of fresh air to aid in combustion — in fact it is required for most new installations to prevent backdrafting and poor performance of furnaces, water heaters, and exhaust fans. Fresh air supplies should have a well-sealed damper to prevent air leakage when not in use.

- The joint where a brick or stone chimney meets the wall or ceiling can be a source of air leakage. Foam or caulk to prevent unwanted air flow.

Seal fireplaces

There are several ways to improve the energy efficiency of a fireplace, including:

- Seal flue damper.

- Install air-tight doors (with good gaskets).

- Install a “chimney balloon” in seldom used fireplaces.

- Ensure proper operation/sealing of fresh air supply if it exists.

- Caulk/foam where brick/stone meet wall and ceiling.

Exterior sealing: stop moisture damage, too

Sealing on the outside of your home not only prevents air from entering, it can also prevent damage to siding, walls, insulation, windows, and doors due to moisture intrusion.

Holes for pipes, wires, etc.

- Caulk or foam around openings for electric, gas, oil, and water-supply lines; drainage pipes; plumbing for outside spigots; cable TV and telephone cables; mail slots/doors.

Vents

- Caulk or foam around dryer vents, heating and cooling system vents, and fresh-air supply vents for fuel-burning furnaces and water heaters.

Windows

- Caulk around window frames. If you have combination storm windows, caulk around the windows where the metal storm window frame meets the window’s frame; don’t seal the moisture weep holes at the bottom of the frame. If you have wooden storm windows that must be exchanged for screens in the spring, use non-permanent, non-staining rope caulk to seal the joint between the storm window and the frame.

Doors

- Caulk around door frames. Install storm doors if needed and check latches and seals.

Seal the outside

There are many places to apply caulking or foam to weather seal the exterior of your home:

- doors and windows;

- vents for furnaces, dryers, water heaters, air exchangers;

- entry points for wires, pipes, cables, faucets.

Keep heated and cooled air in ducts

The ducts for a forced-air heating and air-conditioning system can be one of your home’s biggest energy wasters, especially if those ducts run through unheated or uncooled spaces (like attics or crawl spaces).

Properly sealed ducts can deliver heated/cooled air where you need it, instead of leaking out where you don’t. This allows your furnace/air-conditioner to work less to make you comfortable.

- Check the ducts for air leaks. Repair leaking joints first with sheet-metal screws; then seal joints with either latex-based mastic with embedded fiberglass mesh or metal/foil tape (UL 181). Don’t use plastic or cloth duct tape because it will harden, crack, and lose its adhesion in a very short time.

- Wrap the ducts with special duct insulation; don’t use leftover insulation from other jobs. Seal all insulation joints with the appropriate tape.

- Make sure ducts fit tightly to the register openings in floors and walls; if they don’t, seal them with caulk.

- Seal return ducts to obtain proper air circulation so you do not breathe unwanted basement or crawl space air.

- Make sure registers and baffles are adjusted properly to distribute heated and cooled air to where you need it. For example, in the winter close registers in unused rooms.

- Don’t confuse duct-sealing with duct-cleaning! There are no energy-related benefits to duct-cleaning.

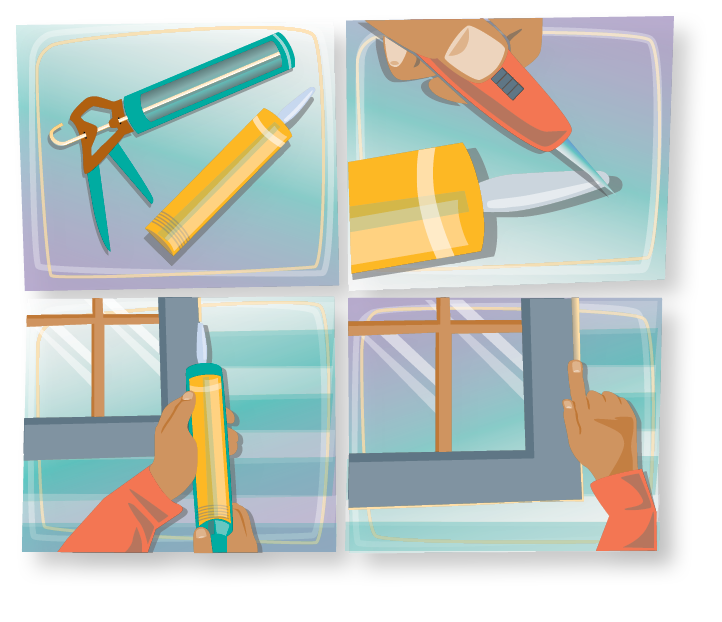

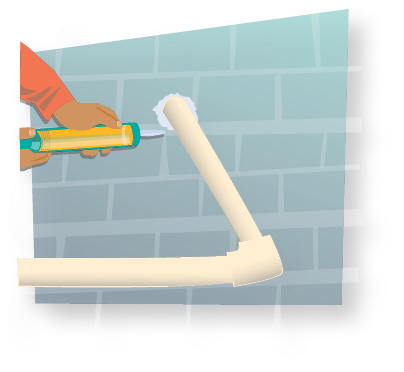

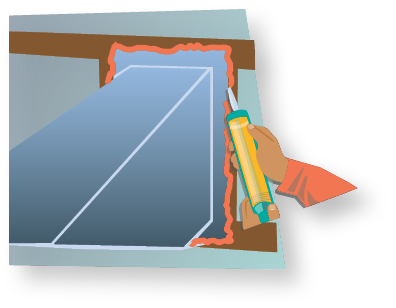

Caulking is easy and cost-effective

Use caulk to seal air leaks in spots such as the cracks and gaps between exterior window and door frames and your home’s siding. Generally speaking, you can seal openings up to ¼ inch with caulk alone. For larger gaps, you’ll need to add a backing material before caulking or use a spray foam sealant instead.

Older wood windows may have glass panes that are held in place with putty and glazing points. If the putty is cracked or missing, it is a likely air leakage location and must be re-puttied. (Broken panes should be replaced.) Although caulking may be used to repair/replace window putty, it may be difficult to apply neatly and make future repairs a challenge.

When shopping for caulk, you may be overwhelmed by the choices, so be sure to read the labels on the tubes and choose the caulk that will work best with the materials you’re sealing. Most types of caulk are sold in tubes that fit a caulking gun. In addition, some caulks come in aerosol cans; they’re a good choice for filling gaps up to ½ inch. If your budget allows, spend a little more for a higher-quality caulk. The benefit will be a longer-lasting seal; inexpensive caulks may last only a few years, while premium caulks will last much longer. Also note that some caulks are for indoor use only, and that some are paintable—while others are not.

Before caulking, note the following points:

- Remove old caulk and loose materials completely.

- Make sure all surfaces are dry and free of dirt, grease, or oil; wipe with rubbing alcohol to clean.

- Do not apply when below 50 degrees F or when rain is possible before curing is complete.

- Tape the edges of the crack to keep caulking off adjoining surfaces.

Follow these tips to get a neat, uniform bead of caulking:

- Cut the nozzle at a 45 degree angle at the point where the diameter is equal to the size of bead you need—near the end for a small bead, farther up for a wider one.

- While applying constant pressure on the trigger, hold the gun at a 45 degree angle and move it slowly along the joint you are sealing.

- Make sure you have enough caulk in the joint to seal both edges and allow for any shrinkage.

- Smooth the caulk with a wet finger (disposable gloves are a good idea!) or a plastic spoon for materials such as silicone or oil-based caulks.

Once you have applied the caulk, it takes time for it to dry, or cure. Curing time is described two ways. The tack-free time tells you how quickly the fresh caulk’s outer surface will dry — or skin over. The total cure time indicates the time required for the caulk to become completely stable — or reach the point where no further drying or shrinking will occur.

Most caulks pose no known health hazards after they’re fully cured. However, some high-performance caulking compounds contain irritating or potentially toxic ingredients, and you should apply them only when there is adequate ventilation; carefully read the manufacturer’s instructions and take the appropriate precautions. In addition, make sure pets and people do not come into contact with fresh caulk.

Use expanding foam for large gaps

Expanding foam is ideal for filling larger cracks that caulks can’t handle. It comes in aerosol cans and takes a short time to cure. The foam is very sticky and attaches itself quickly to whatever it touches, so be prepared to pick up any messes fast.

- You also can use foam instead of caulk for sealing in your attic; low-expansion foam will stick better to dusty and dirty surfaces than caulk (see section on attic sealing in this guide).

- Low-expansion spray foam should also be used to seal the space between framing and jambs in windows and doors; standard expanding foam can cause jambs to warp and affect operation of the window or door.

- When you’re working in a large area such as your attic, it may be inconvenient to carry and keep track of several cans of expanding foam. Instead, consider renting a contractor’s foam gun, which has a long nozzle and can help you get into tough-to-reach spaces.

Try these materials for special jobs

In addition to the types of caulk and spray foam sealant described above, you may need to use fillers to plug extra-wide gaps. Fillers come in a wide variety of materials — cotton, fiberglass, foam, and sponge rubber — and you can find them in the caulking department of your local hardware store or home center. However, these fillers are not designed for exposure to the elements; you’ll need to caulk or seal over them.

- To close gaps too wide for foam, use foil-faced bubble wrap. For really large holes, cut sections of rigid foam insulation to fit and glue into place with expanding foam — before covering with wood or another appropriate building material.

- For winter, use rope caulk to seal windows and other spots that you’ll want to be able to open during the spring. Rope caulk is a gray, putty-like material that comes in long strips or rolls. It’s easy to install and remains flexible, and you can just pull it off when the weather turns warm. Note that rope caulk will not last longer than a year, and oil-based rope caulk may stain painted areas.

Steps to caulking

Laying a consistent bead of caulking can take some practice. Follow these steps to provide a good seal:

- Insert tube into gun.

- Cut tip at 45 degree angle at desired thickness; use wire/nail to break seal at base of spout.

- Squeeze trigger while moving tip steadily along joint to be filled.

- Smooth bead with tool or finger, making sure both edges are covered.

Insulation: a Blanket for Your House

Insulation slows down the heat flow through a building’s envelope. It works year-round to make your home more comfortable and energy efficient. In the winter, it slows heat loss and condensation buildup. During summer months, insulation reduces heat gain and helps keep your home cool.

Adding insulation to your home can cut heating and cooling costs 15 percent or more, depending on factors such as the amount of existing insulation in your home, house size, air leaks, personal energy use, and living habits. Many variables affect the exact amount you’ll save, but insulating your home is often a wise energy investment.

While every house is different, the basic rule of insulating is the same for all homes: Install insulation on any surface separating a heated space from an unheated space. Even if your home already has some insulation in these areas, there can be great benefits in adding more insulation, especially in your attic.

Recommendations vary for the amount of insulation necessary in particular locations for peak energy savings, depending on factors such as climate conditions, the sections of your home being insulated, and the kinds of materials used in your home’s construction.

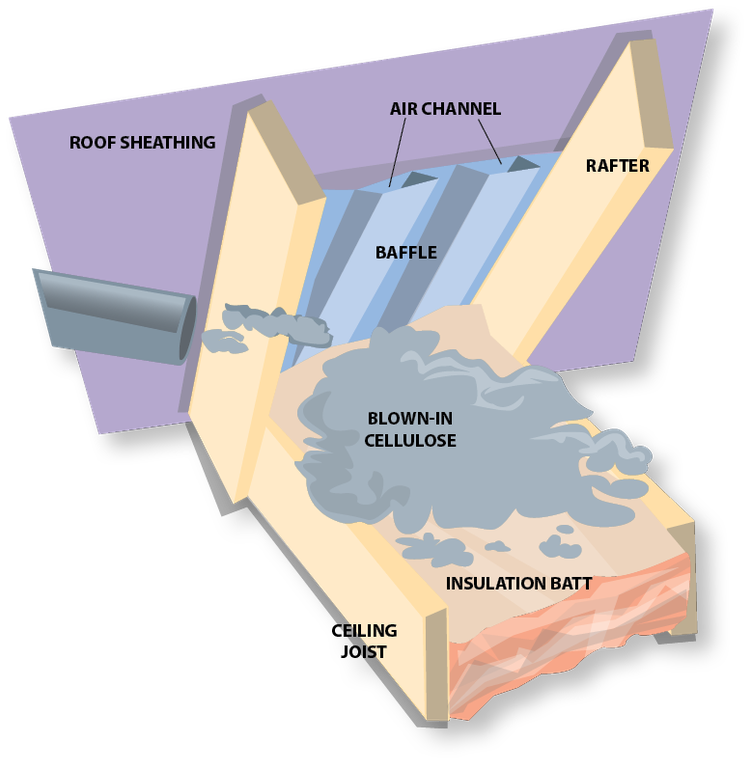

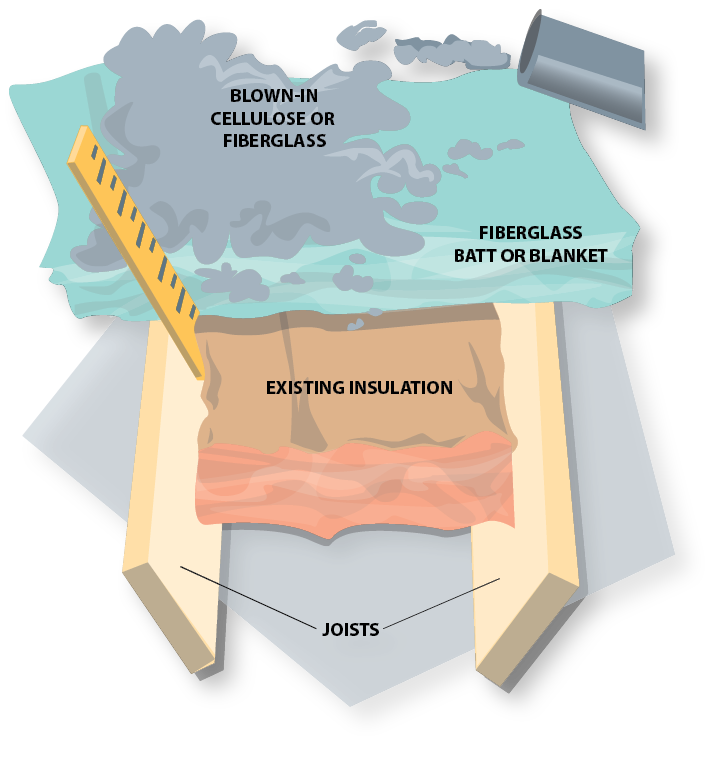

Start in the attic

Your home can lose a significant amount of heat through the roof, so the best place to start insulating is the attic. Compared to walls, access to the attic is relatively easy, therefore the cost of attic insulation projects are considerably lower; it is also the easiest place for “do-it-yourselfers” to begin. You can install loose-fill, batt or blanket insulation over existing insulation. If you choose to use a blown-in or sprayed on insulation such as cellulose, polyurethane or polyicynene, you’ll probably need to have it professionally installed.

Even though most home attics in cold climates have some insulation; many homes can benefit by adding more attic insulation. Increasing attic insulation to an R-50 can provide a good barrier to heat loss. To determine the present R-value of your attic insulation, have an energy audit; you can also measure the height of the insulation and multiply times the R-value per inch of the material that is in place (2.5 to 4.0 per inch, on average). Roughly 12 to 20 inches (depending on the material used) will provide an R-50 rating. Although it generally won’t hurt to add more, the return on the investment decreases as the R-value increases above R-50.

Things to look for if you do it yourself

If you are insulating your own attic there are several things to check out to ensure the best possible results:

- Check for attic air leaks around pipes, wires, and chimneys and seal them up!

- Make sure baffles are installed at eaves to allow ventilation and prevent “wind-wash” of insulation.

- Inspect wires and fixture boxes before covering with insulation.

Seal Air Leaks First

Make sure to seal air leaks into the attic from the living space before adding insulation.

Vermiculite

Loose-fill vermiculite or perlite may be found in older homes but is no longer used for home insulation. Because of the risk of asbestos in some vermiculite, it is strongly recommended that homeowners do not disturb these materials. In some cases, insulation can be installed over vermiculite in attic locations — but only by trained insulation contractors. Should vermiculite removal be necessary, a licensed asbestos removal company should be engaged.

Attic insulation options

There are several good options for adding additional insulation to an attic. Unless wet from roof leaks or moisture from the building below, there is no need to remove existing insulation. Your choices include:

- Batts or blankets. Fiberglass is available in a variety of thicknesses and widths, and can be laid on top of existing insulation. If the top of the existing insulation is below the top of the ceiling joists, fill the spaces between the joists first. Then lay batts or blankets perpendicular to the joists to provide the best coverage. Carefully cut around pipes and truss pieces, and don’t bunch or fold the fiberglass.

- Blown-in. Generally composed of cellulose (made from recycled newspaper) or fiberglass fibers, blown-in insulation does a much better job of filling around framing and providing a consistent layer of insulation. Blown-in insulation can be applied directly over existing insulation. Proper application requires a special machine and moderate skill.

Regardless of which insulation material is selected, plastic baffles must be inserted between rafters extending past the wall plate to keep insulation from falling into soffits and to provide ventilation. Every attic insulation project must also include sealing of air leaks!

What about open ceilings or flat roofs?

Insulating a cathedral ceiling, A-frame house or flat roof is an especially difficult job, because there is little or no space between the ceiling and roof. One option is professional installation of spray-in insulation materials; alternatively, building out of roof rafters to allow additional insulation is also possible. A third option is to have foam insulation applied beneath the roof deck during a re-roofing project. All options must also provide appropriate ventilation to current code.

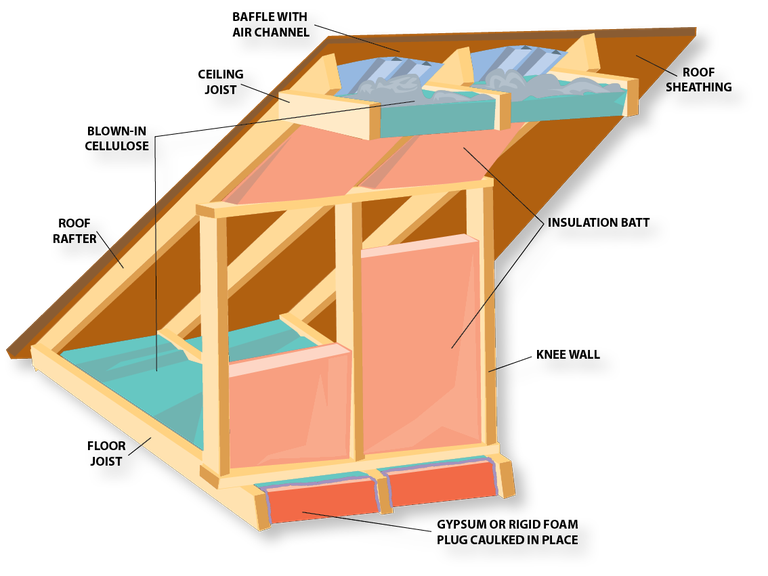

Insulating the “story-and-a-half”

Many homes built in the middle of the 20th century were single-story with a large “expansion attic” above. These areas frequently became finished living space — and were often uninsulated or insulated improperly. Because of the complexity of the framing and the difficulty gaining access to some of the areas that need to be insulated, the story-and-a-half can present an insulation and air-sealing challenge. But, considering that so much heat can escape through the top of a building, proper air-sealing and insulating of these structures is essential.

If the attic space has never been framed or finished, insulating and air-sealing can follow the standard practices as if it were new construction. If, however, knee walls and ceilings are in place, special care must be taken to ensure a good result. (Note that the same approaches to sealing and insulating also apply to homes that have an attic above a second floor — a “two-story-and-a-half.”)

Four surfaces must be sealed and insulated

There are four parts to a typical story-and-a-half framing system (along with the vertical gable ends). Each part requires a slightly different approach to provide proper air-sealing and insulation.

Ceiling

- The flat ceiling is similar to an attic floor. Batts or blown-in insulation can be installed between and over the ceiling joists. Access to the space may be through an attic door or through roof vents. If the knee wall space is unheated, baffles must be installed for ventilation. Air-sealing of all penetrations (access doors, wires, fixtures, vents) must also be done.

Slants

- The slanted part of the wall should be treated like a cathedral ceiling. Building out the rafters to allow for additional insulation and ventilation is the best solution. Professional installation of a spray foam is also possible, as well as rigid foam under the roof decking. If the space behind the knee wall is to be kept as heated storage, the insulation needs to extend all the way to the floor along the slants.

Walls

- The vertical walls (knee walls) can be insulated and sealed just like vertical walls on the lower part of the house, with the following exceptions:

- If the knee wall space is heated storage, no knee wall insulation is required (see slants, above).

- If the knee wall space is unheated storage, the knee wall should be insulated like any vertical wall. Gypsum (or foam boards for additional insulation) can be installed over the studs on the knee wall side to protect the fiberglass. Air-sealing of all penetrations (access doors, outlets, wires, vents) must also be done. If there are built-in drawers or cabinets, a sealed and insulated box must be built around them on the knee wall (cold) side.

Floor

- The space between the floor joists beneath the knee wall is often neglected in terms of insulation and sealing — and is often the most difficult to access. If the knee wall space is heated storage, no floor joist insulation is required. Otherwise, insulation must be installed beneath the floorboards from the outside junction with the roof to a point beyond the knee wall. The methods include:

- Removing floorboards to place batts between the joists. A “plug” of gypsum or foam insulation board should be installed beyond the knee wall, caulked or foamed to prevent air leaks.

- Drilling holes in the floorboards to install dense-packed cellulose insulation. Because dense-packed cellulose provides an air barrier, no additional air-sealing is required.

Knee wall insulation

Attention to detail is critical when insulating and sealing the knee wall area in an expansion attic. Any insulation voids or unsealed cracks will allow large amounts of air to escape, reducing thermal performance and increasing energy costs.

EXTEND BAFFLE THE LENGTH OF THE INSULATED SLANT

Head for the basement

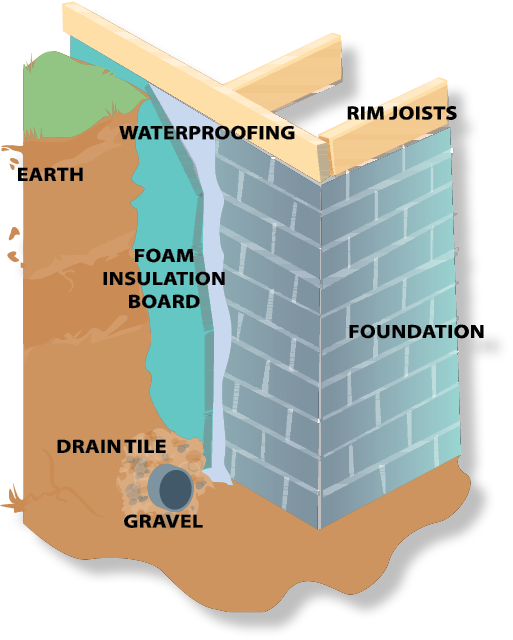

Many homes have basements with either concrete block or poured-concrete walls. While these make sturdy foundations, they’re poor insulators and have a very low R-value. Soil is also a very poor insulator. Therefore, an uninsulated basement can account for a significant amount of a home’s energy loss.

Check the top of the basement foundation

The wooden band (or rim) joist area — where the house’s wooden structure rests on the concrete foundation — is the best place to begin. It’s the simplest and least expensive basement area to insulate, and it will bring you the highest return on your investment. And, because it is above ground, there is little risk of moisture migration from the exterior.

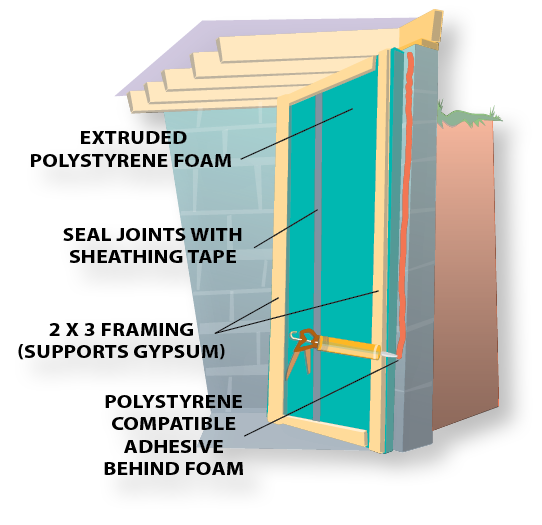

Insulate (to R-19) with expanding spray foam or cut-to-fit pieces of rigid, extruded polystyrene or polyisocyanurate foam, caulked or foamed into place, to avoid air leaks. Fiberglass is not recommended because it does not provide an air-tight seal. Moisture from the basement can migrate through the fiberglass where it condenses on the cooler rim joist, leading to potential problems with mold or wood rot. Additionally, code requires that exposed polystyrene foam insulation be covered with a fire-stop material; a piece of gypsum board foamed or caulked in place is usually sufficient.

Insulating the foundation walls

Concrete (whether block or poured) is extremely porous, and unless sealed from the outside it is a likely source of moisture into a basement. Because migrating and condensing moisture can be trapped behind wall insulation — leading to mold and mildew growth — insulating basement walls is challenging. Even historically dry basements can be subjected to water migration or seepage during severe storms or flooding. (Don’t be misled by claims that products that are painted or applied to interior basement surfaces will prevent moisture from seeping through walls or floors — they can’t.)

Attaching wooden studs to the foundation wall and installing fiberglass insulation (a method used in previous years) is no longer recommended. The wood and insulation can become a good medium for growing mold and mildew should any moisture find its way between the foundation wall and the insulated wall.

The interior of basement walls can sometimes be insulated successfully with rigid foam panels; proper assessment and installation by a professional contractor is strongly suggested, however. Attention to details — such as proper sealing — can reduce the chances of damaging mold and mildew problems. It is important to note again, however, that foundation walls that are not sealed from the outside will potentially allow moisture to migrate into the basement.

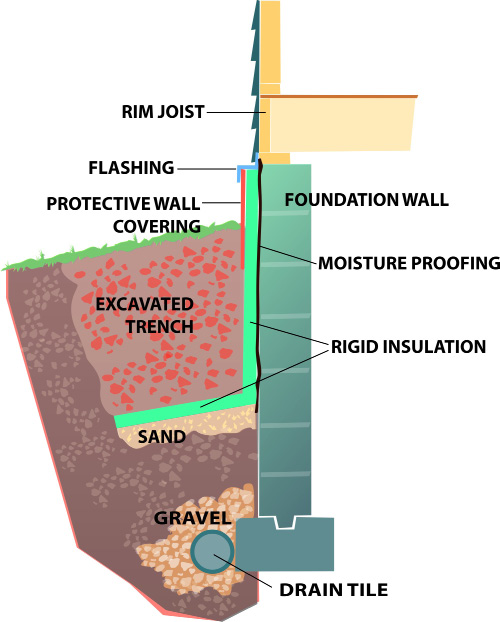

Unfortunately, the recommended approach to basement insulating is also the most costly: removing the soil outside the house all the way to the footing, waterproofing the foundation wall, providing for proper drainage, then insulating with rigid foam on the exterior of the wall. A project of this magnitude requires hiring an experienced contractor.

Rim joist insulation

Caulk or foam in place 3-4" of rigid foam (depending on type). Carefully seal around pipes, wires, and vents to prevent moisture from damaging wood framing. Cover with gypsum board as a fire-stop.

Basement Insulation Options

The best way: exterior

Although usually more costly (in an existing building), the insulation of foundation walls from the outside is the best way to provide thermal efficiency and protection from moisture problems, mold, and mildew. Proper sealing and drainage are important in any exterior foundation insulation project.

Another exterior option

An alternative to insulating and sealing all the way to the footing on the exterior foundation wall is to do it part way (sometimes called the “apron” method). Dig a trench about two feet wide and about 18 inches deep and insulate the wall with a vertical piece of rigid foam. Then place a horizontal piece of rigid foam slanted away from the wall at the foot of the vertical piece. This approach will provide some insulation for the basement wall and (if done properly) can aid in reducing the intrusion of water through the basement wall. Attention to detail regarding flashing, surface preparation, and joint sealing will reduce the likelihood of basement water problems.

From the inside

Because of the risk of mold and other moisture problems, the insulation of interior basement walls is very challenging to do properly. Fiberglass batts are no longer recommended! The steps outlined above are guidelines; attention to details is essential in order to reduce potential problems and provide complete thermal insulation.

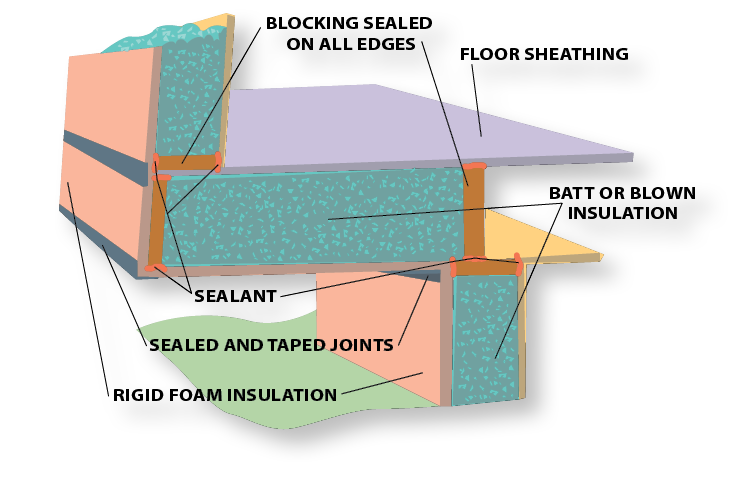

Insulate floors over unheated spaces

Floors over a basement that have a heat source such as a furnace, boiler, or wood stove don’t need to be insulated. However, floors over an unheated area such as a garage, a porch, or open ground can be a source of considerable heat loss. Window projections (such as bay or bow windows) also need to be insulated and sealed where they protrude from the surrounding wall.

- A cantilevered floor over an exterior wall needs insulation and air-sealing just as much as any other exterior surface. Depending on how the floor is built, there are several ways to make cantilevered floors more efficient. One is to hire a professional to spray in polyurethane, polyicynene, or blown-in cellulose insulation through small holes on either the interior or exterior. If you insulate this area yourself, use R-19 batts with a vapor retarder facing toward the heated part of the house. Air-sealing is critical to prevent moisture from damaging insulation or building components.

- Use rigid board insulation or spray-in foam to insulate the “floor” and the “roof” of a bay or bow window projection.

- If your home was constructed slab-on-grade, the cold slab can damage wood and carpets if water and ice condense on the floor. During construction, rigid board insulation should have been installed underneath and around the entire perimeter of the slab. If not, a professional can insulate the slab using rigid insulation board with plywood flooring on top.

If you have an unheated crawl space:

Any part of the house that is heated must be separated from unheated space by insulation and air-sealing, including crawl spaces. If your crawl space has a dirt floor, cover it with polyethylene sheeting before insulating and extend the plastic several inches up the walls. Options include:

- Insulate crawl space foundation walls to a value of R-10 or higher with a rigid foam insulation, appropriately sealed.

- A less desirable option is to insulate between the floor joists with sprayed foam or rigid foam to a minimum of R-10. (Because of the difficulty of a proper air-sealed installation, fiberglass batts between the joists is not usually recommended.)

Regardless of the method used, crawl space ventilation is not recommended, due to moisture and condensation concerns.

Cantilever insulation

Any projection over an exterior wall should be insulated and sealed to prevent heat loss and moisture intrusion. If fiberglass is used to insulate, sealant (caulking or spray foam) should be applied at all framing joints and cracks. Rigid foam boards should be taped at corners and joints.

Check out your walls

Generally speaking, homes built before 1960 often do not have insulated walls, or are insulated with products that are inadequate by today’s standards. Even some homes built after that often were not carefully or completely insulated as would be done today. The benefits of adding insulation to exterior walls can be very high, depending on the situation. There is a simple way to determine whether your walls contain insulation: Turn off the electricity and remove an electrical outlet or switch plate on an exterior wall; using a flashlight, look behind the electrical box for insulation. This approach will tell you only whether or not you have any insulation material in your walls; the integrity of the installation can only be determined through an energy audit that includes infrared imaging.

When should you add wall insulation?

Insulating your walls is generally a good idea when there is less than one inch of insulation in the wall cavities (typically, walls have space for 3½ inches of insulation) or if infrared imaging reveals significant voids or gaps. If remodeling work is planned involving exterior walls, adding wall insulation (and proper air leak sealing) is relatively easy and affordable. It also makes sense to consider insulating your walls when replacing your home’s siding.

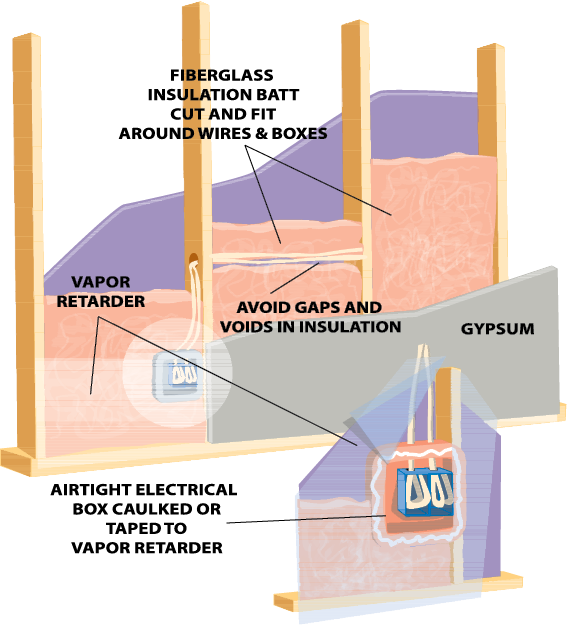

Fiberglass batts

If your wall cavities are accessible from the inside (because plaster or gypsum has been removed), installing fiberglass batts is relatively straightforward. Careful cutting and fitting around wires, electrical boxes, pipes, and vents is very important. When fiberglass is compressed, it loses significant insulating value; when “bunched up” (around wires, for example) there can also be voids and gaps. Installing a vapor retarder over the fiberglass is also important; seal all seams with sheathing tape. Outlets and switches should have an air-tight box installed that is taped or caulked to the vapor retarder.

Dense-pack cellulose

Drilling small holes (from the inside or outside) and adding dense-pack cellulose can provide good insulating value, and excellent air-sealing as well. Installed by an experienced contractor, dense-packing exterior walls also requires patching and finishing the access holes (which can be a challenge with exterior finishes). Because of the higher cost of this type of project, consider it only after the rest of your home has been tightened and the attic has been sufficiently insulated.

Wall insulation

Dense-pack cellulose (made from recycled newspapers) is an excellent choice for insulating and sealing walls. It is frequently the most cost-effective way to insulate sidewalls in homes with no existing wall insulation.

Other wall insulation options

Depending on the situation, other options for wall insulation may include:

As part of re-siding.

- Removing old siding and installing new provides several insulation options. Insulation can be blown into empty stud cavities through holes in the exterior sheathing before the new siding is installed. Another option is to install rigid foam sheathing beneath the siding to provide additional wall insulation and provide a thermal break for the wall framing. (Don’t be fooled by claims that foam “backer-boards” placed behind siding offer insulation value; they are designed to support the siding, not insulate the walls.)

Spray foam into open cavities.

- Polyurethane or polyicynene foams can be sprayed into open wall cavities. These products provide a very high R-value and a good air barrier and vapor retarder as well. Because of the complexity of the equipment and application process, spray foams are usually only installed by experienced contractors.

Insulation is rated by R-values

The R-value (or thermal resistance) of insulation is a measure of its ability to resist heat loss or heat gain. The higher the R-value, the better a material insulates. It’s important to note that an insulation’s R-value is based on its performance in a 70 degree F environment with no air movement. Ironically, those ideal conditions are not what you would usually find in your attic or walls! Therefore, the effective R-value of a particular insulation may be much lower than its rated R-value, especially if the insulation is not properly installed — or if air leaks are not sealed before the insulation is added.

When you go shopping for insulation, it’s important to remember that the product with the highest R-value per inch may not be the most cost-effective one. For example, when insulating a basement wall to an R-12 value, using 3 inches of an R-4 per inch insulation material might be less expensive than using 2 inches of an R-6 per inch product. To get the most insulating value for your money, compare the total costs of insulating an area to a specific R-value.

In addition, blown or loose-fill insulation materials will settle after installation, reducing their effective R-value by 10 percent or more. (Dense-pack cellulose for use in wall or floor cavities, however, has negligible settling.) Be sure to check the manufacturer’s specifications before you buy insulation, and follow supplied charts to ensure adequate long-term coverage.

Finally, some types of insulation — such as dense-packed cellulose, polyurethane, and polyisocyanurate — combine both an air-sealing barrier and insulation in one step. Some insulation products also serve as a vapor retarder when properly installed. When comparing products carefully consider the costs and benefits of doing the entire job: insulation, air-sealing, and vapor retarder.

Infrared Thermometers

NDSU Extension developed a publication and procedure for using an infrared thermometer to get a general idea of how much insulation is in exterior walls.

Insulation needs a vapor retarder

As with a glass of ice water, condensation occurs when warm, moist air touches a cold surface. When this happens in your home, it can cause mold, mildew, and damage to building materials and reduce the effectiveness of the insulation.

A vapor retarder slows the movement of air and water vapor through building materials; in fact, a good vapor retarder will allow very little moisture to pass through. Some vapor retarders also serve as air barriers. A good vapor retarder and good air-sealing can improve the energy-related performance and durability of your home.

Most homes built before 1970 do not have a separate vapor retarder component; however, the predominance of oil-based paints in those homes usually provides an adequate vapor control function.

Whenever you install insulation, you always should determine if a vapor retarder is needed as well. If you’re adding insulation to an area that already has a vapor retarder, you do not need to add another one. Vapor retarders include:

- Polyethylene sheets are most frequently used as a vapor retarder, vapor retarders should be placed on the warm side of the insulation. In northern climates, the vapor retarder is behind the drywall on the interior of the home; in southern climates, the temperature generally would be warmer on the outside, so the vapor retarder would be on the outside of the home.

- Foil or kraft paper often is part of fiberglass batt or blanket insulation but may not be an adequate vapor retarder. The vapor retarder should face the interior of the building.

- Most rigid foam board insulation acts as a vapor retarder when installed under an interior covering material such as drywall. If the foam is also intended to be an air barrier, the seams should be taped — for both interior and exterior use — to improve its performance. Do not use foil-faced insulation on the exterior of a house.

- Sprayed-in foams (such as polyurethane insulation) may not need a vapor retarder when installed properly. Check your local building codes for vapor retarder requirements with spray foams. Depending on the density of the foam, generally more than 1 inch will serve as a vapor retarder.

- “Smart vapor retarders” are a relatively new product that allows moisture to migrate out of a wall cavity under certain conditions. Consisting of a film that is applied over un-faced fiberglass or other insulation (similar to polyethylene sheets), smart vapor retarders have a high resistance to water vapor under low-humidity, winter conditions, thus slowing moisture movement from the inside environment into the wall. During high-humidity, summer conditions, the permeability adapts, thus permitting any trapped moisture in the walls to migrate to the interior.

- Finally, vapor retarder paint (often a primer sealer) can provide adequate vapor control and can be applied to new or previously painted interior surfaces.

Types of insulation

Insulation does its job by creating small pockets of air that slow the transfer of heat through the insulation — in exactly the same way that a blanket works. Types of insulation vary according to use and location. Among the insulation options that work best in cold climates are the following:

Batts or blankets

|

Material |

Fiberglass, rock (mineral) wool. |

|

R-value/inch |

3.1 to 4.0 |

|

Method of installation |

Fitted between studs, joists and beams. |

|

Where applicable |

All unfinished walls, floors and ceilings. |

|

Advantages |

Do-it-yourself. Suited for standard stud and joist spacing that is relatively free of obstructions. |

Loose-fill

|

Material |

Cellulose, fiberglass, rock (mineral) wool. |

|

R-value/inch |

2.4 to 4.0 |

|

Method of installation |

Blown into place (attics) or dense-packed (cellulose, walls). |

|

Where applicable |

Enclosed existing wall cavities or open new wall cavities. Unfinished attic floors and hard-to-reach places. |

|

Advantages |

Commonly used for retrofits (adding insulation to existing finished areas). Good for irregularly shaped areas and around obstructions. Dense-pack cellulose in walls also provides an air barrier. |

Rigid foam

|

Material |

Extruded polystyrene foam (XPS), expanded polystyrene foam (EPS or beadboard), polyurethane foam, and polyisocyanurate foam. |

|

R-value/inch |

3.5 to 7.5 |

|

Method of installation |

Interior applications — must be covered with ½-inch gypsum board or other building-code approved material for fire safety. Exterior applications — must be covered with weatherproof facing. |

|

Where applicable |

Basement walls, exterior walls under finish materials and vented low-slope roofs. |

|

Advantages |

High insulating value for relatively little thickness. Can block thermal leak when installed continuously over frames or joists. Can provide both air barrier and vapor retarder. |

Spray foam

|

Material |

Polyurethane, polyicynene. |

|

R-value/inch |

3.6 to 7.0 |

|

Method of installation |

Sprayed onto surfaces or behind a net facing. |

|

Where applicable |

Open wall cavities, between roof rafters. |

|

Advantages |

High insulating value for relatively little thickness. Provides good air barrier. Some products provide vapor retarder. |

Windows and Doors

Windows, doors, and skylights are often a weak energy link in home construction, accounting for a significant portion of a home’s heat loss in the winter and heat gain in the summer.

Many complaints about condensation or frost on windows and doors and about drafts or temperature discomfort in a house are actually caused by air leaks. Although new technology has greatly improved the energy efficiency of modern products, any fenestration (opening) will be far less efficient than the surrounding wall structure — especially one that is properly insulated and air-sealed. Because new windows and doors are relatively expensive, it is important to determine when repairs make sense and when replacement is the right choice.

When to repair windows and doors

As homes age, building materials age as well, losing strength, flexibility, and usability. This disintegration process can be slowed considerably, and — surprisingly to many people — replacement of windows and doors may not be necessary if the problems are not structural. Simple maintenance and inexpensive repairs (like caulking, weather-stripping, and painting) can extend the life of windows and doors considerably — and for much less than the cost of new components.

Many older homes have windows and doors that were installed to the standards of their day; as building knowledge has improved, so have the methods of installation. Even relatively new installations can suffer from inadequate materials or poor installation, however. Here are some common problems and fixes:

- Damaged components. Cracked or missing panes of glass in doors or windows are obvious locations for leakage and energy loss. Replacement is best, but sealing with caulking can be a good temporary fix. Older windows may use a glazing compound (putty) to hold the glass to the frame. As this ages it dries and comes loose, allowing air to leak through, and should be replaced. Other damaged parts may be able to be repaired with wood putty or epoxy.

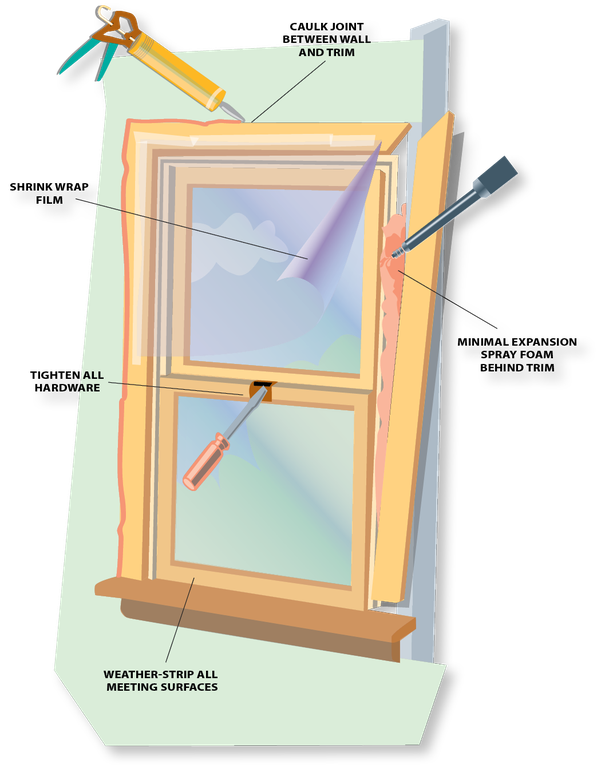

- Defective air-sealing. The gap between jamb and framing may be empty or stuffed with fiberglass insulation. Gently removing inside trim will reveal this space, allowing for application of a minimally-expanding spray foam product or caulking. If re-siding, access to this space may be possible from the exterior. If access to the space is difficult, a small bead of paintable caulking can be applied to the joint between the trim and the wall. A quick and inexpensive (but single-season) solution for leaky windows can be the application of shrink-wrapped film on the inside.

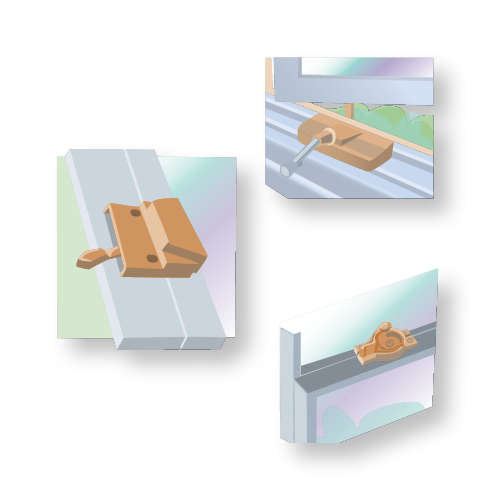

- Loose or missing hardware. Latches, hinges, and the operating parts for crank-out windows can become loose or damaged through repeated use. Often a simple tightening of screws will do the trick. If parts are bent or damaged, replacements may be available from the manufacturer or from a local building supply store.

- Improper exterior flashing. Properly installed flashing diverts water to the outside of the siding, preventing intrusion into the wall or window/door unit. Water that seeps into the wall cavity or structural components can lead to rot and voids, which can permit air to leak around the window or door. If water damage has occurred, removal of the exterior trim (and perhaps siding) and re-doing the flashing is the only way to remedy the problem. If damage to wall assemblies or insulation has occurred, repair and replacement may also be required.

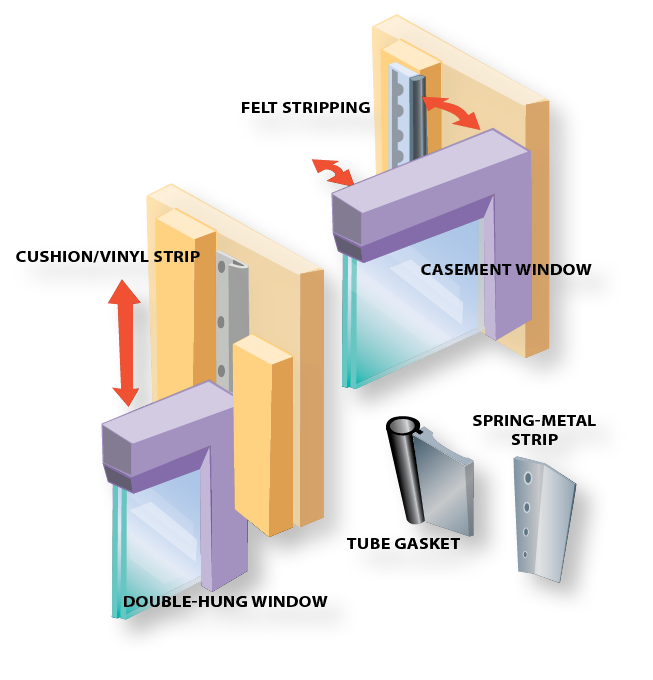

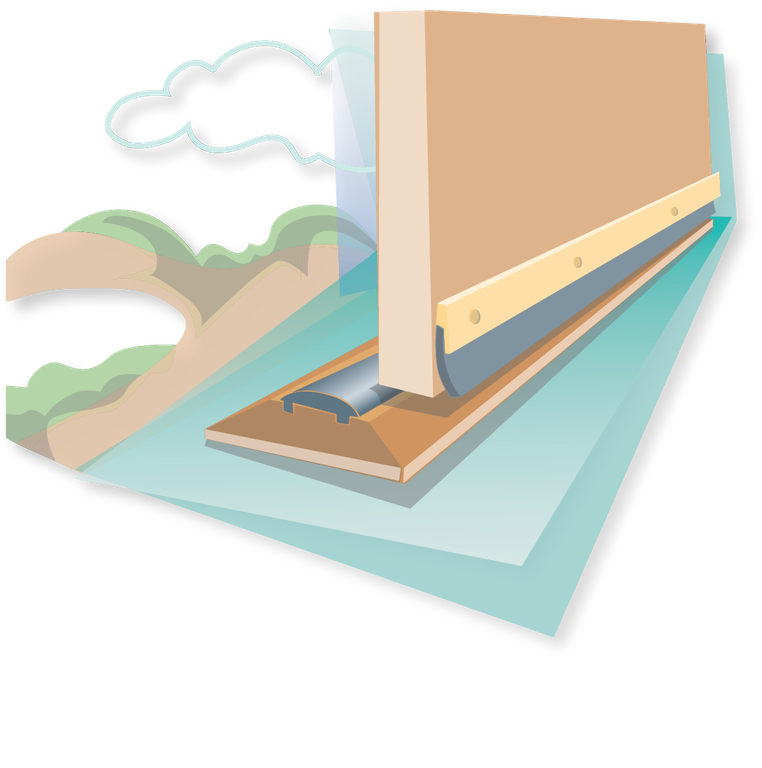

- Worn or damaged weather-stripping. Weather-stripping prevents air infiltration around windows and doors by sealing the gaps between the frames and moving parts when they’re closed. With weather-stripping, one or both surfaces of a door or window must be free to move — as opposed to caulking, which builds a permanent seal between two stationary surfaces. Attention to detail is critical when installing weather-stripping in order to avoid problems with window and door operation. Along with windows and exterior doors, you should also weather-strip all doors that lead to unheated areas, such as the attic, garage, or unheated basement.

Types of weather-stripping

Weather-stripping comes in several sizes and shapes (often designed for specific uses) and may be made from metal, plastic, vinyl, rubber, felt, or foam—or a combination of these materials. Extensive testing has shown that tubular weather-stripping provides the best seal. However, on doors or swinging windows, this type requires the most closing pressure, which may be difficult for children, the disabled, or the elderly. Silicone, neoprene, urethane, or rubber strips are better in these situations. Open-cell foam and felt strips need to be very tightly compressed to create an adequate seal. They will keep out dust, but are inadequate air barriers. Therefore, the installation of neoprene, urethane, silicone, or rubber weather-stripping is recommended, because these materials create good air-seals with minimum closing force at all temperature ranges and have long, useful lives.

Many window and door manufacturers have replaceable weather-stripping kits that can be ordered and easily installed; check with the manufacturer or your building supply store for information about your specific units.

You can also buy weather-stripping by the foot or in kits at a local hardware store or home center. You can calculate the amount of weather-stripping you’ll need by measuring the perimeter of all the windows and doors to be weather-stripped. It’s a good idea to add five to ten percent more for waste. However, before you buy anything, determine what kind of weather-stripping you want to use. If possible, remove a small portion of the existing weather-stripping (or take a picture) to compare it with what is available. Checking the size of the gap between the fixed and moveable sections of your doors and windows, as well as thinking about the amount of expected wear and tear in these areas, will help you decide which material is the most appropriate.

Window hardware

As windows are used over time, the hardware can become loose or worn, leading to incomplete sealing when closed. Tighten loose screws or reposition hardware slightly to make a firmer attachment. If damaged, replace closing hardware with parts from the manufacturer. Some replacement parts are available through hardware stores as well.

Window rehabilitation

The most important energy-related function of a window is to prevent air leakage. Even aging windows can be repaired and tightened, improving energy efficiency and extending their life by many years.

When to replace windows and doors

At some point, repairs may be too costly or time-consuming and replacement may make more sense. But, before you invest in a complete replacement of all components, consider some less-expensive alternatives. Carefully calculate payback when making your decision:

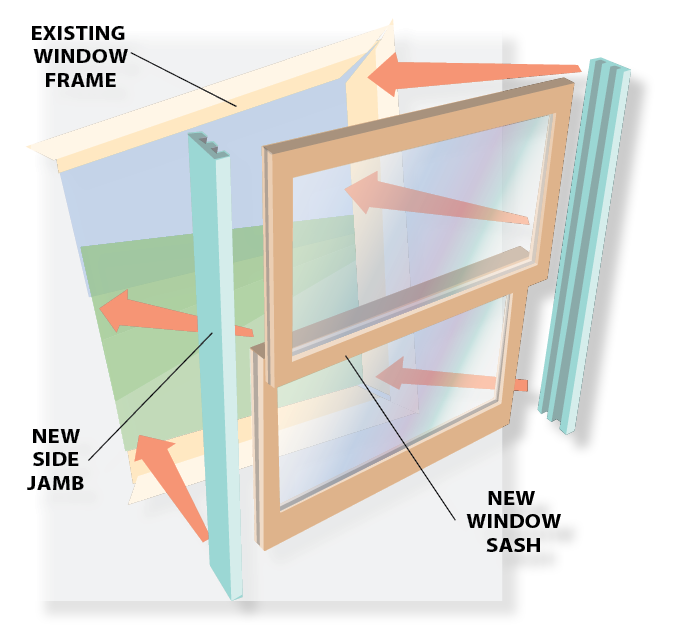

- Replacement window sashes. Older, double-hung windows can have new sashes installed that are multiple-paned and tightly sealed. The window frames remain, and new jamb inserts are installed to accept the somewhat smaller sash units. This approach may not require the removal of interior or exterior trim, and provides an opportunity to seal and insulate all around the unit.

- Replacement storm windows and doors. Aging, damaged, or poorly made storm windows and doors can allow air leakage directly onto the main unit, reducing its thermal performance. Replacing the storms can be considerably cheaper than all new windows and can provide good air leak control as well.

- Interior window coverings. Drapes and blinds are important for reducing solar gain during the summer. They also can be used for winter energy savings, but you need to take care to prevent airflow around the window covering. Any small air leaks can cause condensation and frost buildups, which can lead to component damage.

Weather-stripping

The performance and durability of windows is tied closely to weather-stripping. Materials such as polyurethane, mylar, neoprene, and EPDM rubber are ideal for cold climates because they remain flexible under temperature extremes.

As with windows, weather-stripping of doors is important, especially since most doors are opened and closed more frequently than windows. Materials such as polyurethane, mylar, neoprene, and EPDM rubber are also recommended for doors. Special attention should be paid to the threshold seal at the bottom of the door; subject to considerable wear from foot traffic, it should be durable and flexible.

In addition, since all weather-stripping will have to eventually be replaced, it is important to have materials that are easy to remove and install and are readily available.

Window options

If the basic frame of the window is in good or repairable condition, a jamb and sash replacement may be an economical and efficient choice.

What to look for in new windows

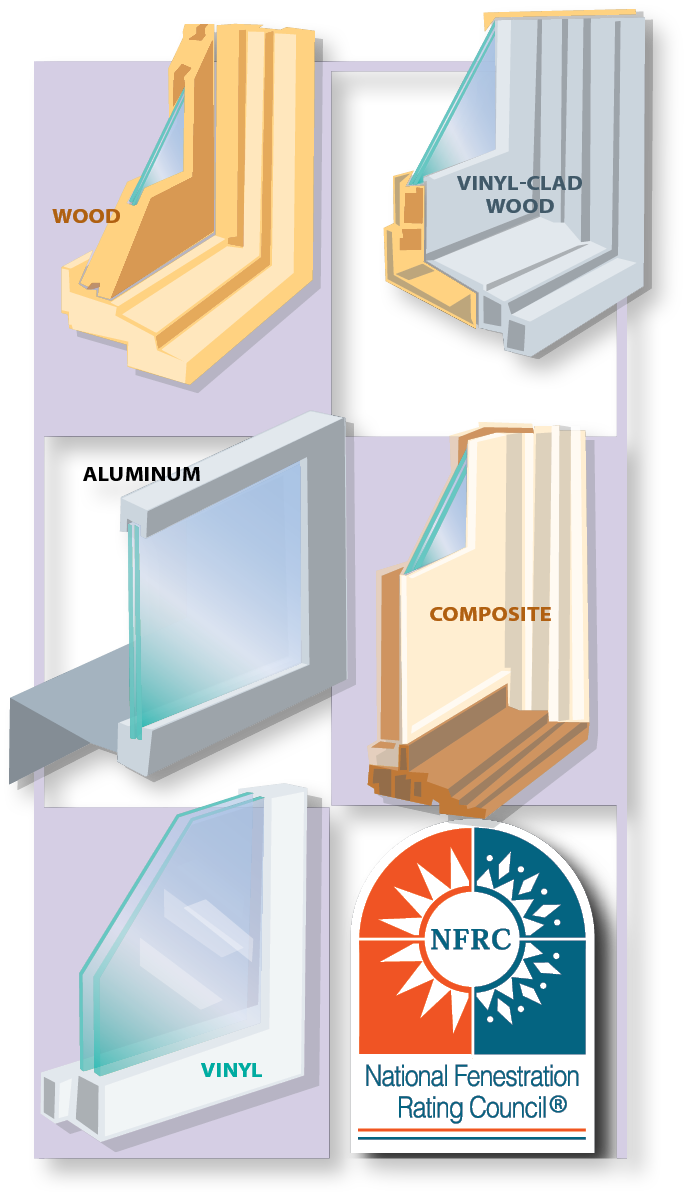

Buying windows can be confusing. There are multiple options available, including the materials used in the frames, the finishes, the types and quantities of insulating and sealing materials, coatings, and more. But for evaluating energy efficiency, there are some basic things to look for:

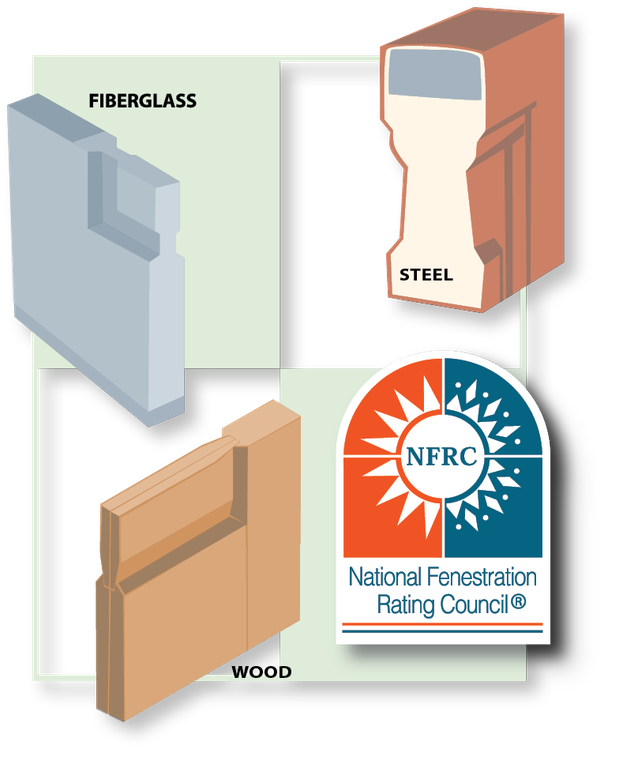

The NFRC label

You should look for a label from the National Fenestration Rating Council (NFRC). The NFRC is a nonprofit organization that provides consistent energy and performance ratings of windows, doors, and skylights. It evaluates products according to several categories, including:

- U-factor: The ability of a window to conduct heat (the inverse of an R-value, used to evaluate products like insulation). U-factor ratings generally fall between 0.20 and 1.20; the lower the number, the better the energy efficiency of the unit. The recommended U-factor for windows is 0.30 or less.

- Solar Heat Gain Coefficient: Measures a window’s ability to reduce heat gain in the summer, thus reducing cooling loads. Based on a zero to 1 scale, a lower number will block more sunlight, reducing solar gain. In cold climates, a good balance of about 0.50 is recommended.

Window options

If new windows are needed, there are several materials and finishes available (above). Check the NFRC label for information about efficiency and performance.

The ENERGY STAR® label

The U.S. Department of Energy and Environmental Protection Agency have developed an ENERGY STAR® designation for products meeting certain energy performance criteria. Since the energy performance of windows, doors, and skylights can vary by climate, product recommendations are given for four climate zones: a mostly heating zone (Northern), two heating and cooling zones (North/Central and South/Central), and a mostly cooling zone (Southern).

Window Features

Several features contribute to the ENERGY STAR® and NFRC ratings, including:

- Multiple glazings. Generally, the more panes of glass (or glazings) the better the insulating quality of the window. Double-paned windows are the standard in new windows; triple-panes in certain applications (large or fixed windows, for example) can improve thermal performance.

- Gas filling. The space between the glazings can be filled with inert gases (such as argon or krypton) that are better insulators than air.

- Low-e coatings. Adding a metallic coating to the glass layers can lower the window’s ability to transfer heat.

- Insulating spacer. The material that separates the panes of glass can also conduct heat. Wood or other insulating material is better than metal.

Sash and frame construction

Important to the air leakage and U-factor of a window, the materials that compose the sash and frame also have an effect on maintenance and durability.

- Solid steel and aluminum. Although durable, these materials are poor insulators and have higher rates of expansion and contraction, making weather-stripping and caulking joints more prone to failure.

- Wood. A traditional material, wood is a good insulator and has much less expansion and contraction than other materials. However, wood is susceptible to moisture damage and requires more maintenance.

- Vinyl. Nearly maintenance free and similar to wood in insulating value, vinyl has higher expansion and contraction than wood. It can also be subject to sun damage, peeling, warping, and discoloration.

- Fiberglass. Offers high insulating, lower expansion, and contraction.

- Wood clad. A wood frame covered with metal or vinyl offers good insulation and low maintenance, with lower expansion and contraction.

Proper window & door installation is critical to good performance

As with any product, proper installation of doors and windows will provide the best performance. That means suitable insulation and air-sealing between framing and units, and correct flashing on the exterior to prevent water intrusion.

To ensure warranty coverage, manufacturer’s instructions must be carefully followed, as well as applicable building and energy code requirements.

Remember, a gain in efficiency can be quickly negated by substandard installation or lack of attention to detail. In other words, buying windows and doors with high thermal performance and durability won’t do you much good if they are improperly installed.

What to look for in new doors

Doors, too, offer a wide range of choices for materials, finishes, and insulation. As with windows, the ENERGY STAR® designation and the NFRC label will tell you the energy efficiency of a particular door. U-factor is the most important consideration for doors; a rating of 0.30 or less is recommended. Keep in mind that the more glass area in a door, the lower the thermal performance.

Door Features

Several features contribute to the ENERGY STAR® and NFRC ratings, including:

- Insulated steel. Commonly made with a steel face and filled with polyurethane insulating foam — with a U-factor as low as 0.17 — these doors can exceed the energy performance of a wood panel door considerably. They usually come prefinished and prehung in a weather-stripped frame.

- Wood. Although the traditional wood panel door has the benefits of less expansion and contraction than steel doors, it also has a relatively poor thermal performance (U-factor of about 0.50) and has higher maintenance requirements.