Sugar Beet Byproducts Alternative Feed for Sheep

(Click the image below to view a high-resolution image that can be downloaded)

Drought conditions and increasing livestock feed prices have sheep producers searching for alternative feedstuffs.

Sugar beet byproducts could be a viable option to provide high-quality forage in sheep operations in the upper Midwest, according to Reid Redden, North Dakota State University Extension Service sheep specialist, and Alison Crane, a graduate student in NDSU’s Animal Sciences Department. Minnesota, North Dakota, Idaho and Montana together generate about 74 percent of the country’s sugar beets.

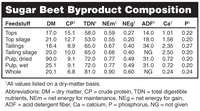

Beet pulp, which commonly is used in beef cattle diets as a supplement or roughage replacement in finishing diets, is the beet shreds left over from processing. This feed is high in energy and fiber and can be purchased in pelleted or dried flake form.

“According to research conducted at NDSU, if used as a roughage replacement, beet pulp has an energy value greater than that of corn silage, and due to the amount of digestible fiber, acidosis is not normally a factor,” Crane says. “As always, rations need to be formulated accordingly to meet the need of whichever group is being fed in your flock,”

Whole sugar beets occasionally can be obtained from processors with spoiled beets or large crops. However, if fed whole, beets could pose a choking hazard to livestock, Crane cautions. She suggests producers use mixer wagons, tub grinders or forage harvesters to break up whole beets.

If the wet byproducts cannot be fed in a timely manner, they can be ensiled. Adding a dry ingredient will help maintain the optimum moisture for ensiling for most beet byproducts.

No nutritional restrictions have been placed on beet pulp in sheep or cattle diets. However, research has shown that if beet pulp is fed at greater than 50 percent in a beef cattle ration (dry-matter basis), reduced intake could occur, Redden says.

Other possible restrictions on beet pulp’s use in sheep diets could include its bulkiness or high moisture content. When deciding whether to use beet pulp as an alternative feedstuff, transportation must be considered as a limiting factor if purchasing wet beet pulp. However, dried shreds or pellets also are available.

Storage bins or commodity sheds are ideal for storage to avoid contamination from moisture or rodents, Redden says. Wet beet pulp most commonly is stored in silage bags or trench/bunker silos.

Another commonly fed beet byproduct is beet tailings. This consists of small beets, broken or damaged beets, soil and any other foreign materials. Tailings are about 80 percent moisture and can vary dramatically in content. If soil contamination can be held to low levels, the feed value can surpass that of corn silage. However, if the tailings contain high levels of soil contamination, the value can be reduced greatly.

“Tailings can be ensiled, but as with the other beet byproducts, they need to be mixed with a dry feedstuff due to their high moisture content,” Redden says.

All of these byproducts are readily available from sugar beet processing. Sheep producers who operate in proximity to sugar processing plants have the greatest opportunity to make use of these products because the wet byproducts are normally quite inexpensive.

Sugar beet processing can result in more byproducts, but beet pulp and tailings are the most commonly fed to livestock in the Midwest.

Sugar beet processing begins in early fall, usually September, and continues through late spring.

“This is a great fit with most sheep operations that need the majority of harvested feeds from January to May,” Crane says. “Sugar beet pulp and other byproducts decline in availability during summer months as the accumulated stores at the processing plants are sold. Most importantly, producers should work with a commodity broker to ensure an adequate supply is available for winter feeding in their operation.”

For contact information on beet processors and product pricing, visit the Partial List of North Dakota and Regional Co-product Prices website at http://www.ag.ndsu.nodak.edu/aginfo/dairy/dairyext/CoProduct.pdf.

NDSU Agriculture Communication - Oct. 18, 2012

| Source: | Reid Redden, (701) 231-5597, reid.redden@ndsu.edu |

|---|---|

| Source: | Alison Crane, (701) 231-7631, alison.crane@my.ndsu.edu |

| Editor: | Ellen Crawford, (701) 231-5391, ellen.crawford@ndsu.edu |