Timing Critical in Late-harvest Wheat Drying

(Click an image below to view a high-resolution image that can be downloaded)

Selecting the appropriate amount and timing of supplemental heat is critical to drying wheat efficiently late in the fall, according to North Dakota State University Extension Service grain drying expert Ken Hellevang.

Drying is a concern in north-central and northwestern North Dakota this year because of the late wheat harvest.

Warming the air when natural-air drying wheat primarily changes the final grain moisture content but increases drying speed only slightly, Hellevang says. The airflow rate determines the drying speed. He does not recommend shutting fans off at night because that will cause drying times to become excessively long.

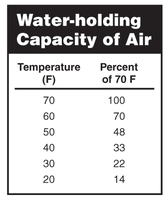

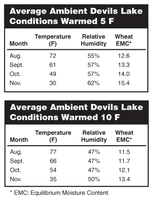

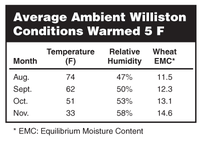

Even for conditions that may occur in the northern part of the state in late September to early October, the air needs to be warmed only about 7 degrees to reduce the relative humidity from 70 percent at 50 degrees to the desired 57 percent at 57 degrees to dry the wheat to 13.5 percent moisture. Because a fan operating at about 6 inches of static pressure warms the air about 4 degrees, a supplemental heater needs to provide only an additional 3 degrees.

A rule of thumb on wheat is that 1 kilowatt (kW) of heat per horsepower of fan motor will warm the air about 5 degrees. Therefore, a 5 horsepower fan needs only about a 3 kW heater to provide the desired amount of heat. One kW equals 3,413 British thermal units.

Without supplemental heat, the final wheat moisture content may be about 14 to 14.5 percent during October drying, depending on weather conditions. Average October weather conditions are 44 degrees and 69 percent relative humidity at Devils Lake and 46 degrees and 64 percent relative humidity at Williston.

Running the fan only during the warmer and drier portion of the day will lengthen the drying time. The estimated drying time is about 50 days to dry wheat from 17 to 13.5 percent using an airflow rate of 0.75 cubic feet per minute (cfm) per bushel with an air temperature of 50 degrees and 55 percent relative humidity. Drying the wheat will take about 100 days if the fan is operated just during the warmer 12-hour period of the day.

Drying takes longer during late fall because the cooler air cannot hold as much moisture, Hellevang says. Drying wheat from 17 to 12.2 percent takes about 27 days with an average August air temperature of 69 degrees and an airflow rate of 0.75 cfm per bushel. Drying wheat from 17 to 13 percent will take about 32 days with an average September temperature of 58 degrees and the same airflow rate.

The drying rate is directly proportional to the airflow rate. If drying 16 percent moisture wheat at 69 degrees takes 21 days using an airflow rate of 1 cfm per bushel, it will take 28 days with an airflow rate of 0.75 cfm per bushel and 42 days at 0.50 cfm per bushel.

The airflow rate must be increased to increase the drying speed. Adding heat to a bin will dry the wheat to a lower moisture content, but the drying time will decrease very little.

Hellevang suggests shutting off the fans during foggy, rainy or snowy weather if it lasts for more than a few hours. However, while wheat at 15 to 16 percent moisture can be without airflow for a few days, wheat at 18 percent moisture should not be without airflow for more than a day or two due to the potential for heating and spoilage.

If drying can’t be completed in the fall, wheat can be cooled to about 25 degrees for winter storage, and drying can be completed in the spring.

For more information about grain drying, visit http://www.ag.ndsu.nodak.edu/abeng/postharvest.htm.

NDSU Agriculture Communication

| Source: | Ken Hellevang, (701) 231-7243, kenneth.hellevang@ndsu.edu |

|---|---|

| Editor: | Ellen Crawford, (701) 231-5391, ellen.crawford@ndsu.edu |

Attachments

- PDF - Water-holding Capacity of Air - (14.1728515625 kb)

- EPS - Water-holding Capacity of Air - (203.7587890625 kb)

- PDF - Average Ambient Devils Lake Conditions Warmed 5 F and 10 F - (16.8173828125 kb)

- EPS - Average Ambient Devils Lake Conditions Warmed 5 F and 10 F - (227.2138671875 kb)

- PDF - Average Ambient Williston Conditions Warmed 5 F - (16.4765625 kb)

- EPS - Average Ambient Williston Conditions Warmed 5 F - (216.0673828125 kb)