Natural-air Dry Grain Now

(Click an image below to view a high-resolution image that can be downloaded)

Now is the time to start spring natural-air drying grain.

“Start natural-air drying corn when the average air temperature is about 40 degrees,” says Ken Hellevang, North Dakota State University Extension Service agricultural engineer and grain-drying expert. “This will be when the nighttime temperature is at least in the upper 20s and the daily high temperature is at least in the 50s. The moisture-holding capacity of colder air is limited, so the rate of drying is slow and drying efficiency is poor at colder temperatures.”

The maximum initial corn moisture for natural-air drying using an airflow rate of at least 1 cubic foot per minute per bushel (cfm/bu) is 20 percent this year due to the increased potential for deterioration with damaged or immature kernels.

The expected drying time for corn is about 45 to 50 days using an airflow rate of 1 cfm/bu. Drying time is proportional to the airflow rate, so at an airflow rate of 1.25 cfm/bu, the drying time is about 35 to 40 days. Adding heat will change the final corn moisture but will change the drying speed only slightly.

Ensure that the fan’s airflow rate is adequate by checking fan charts or estimate airflow by using the fan selection program available at http://www.ag.ndsu.nodak.edu/abeng/postharvest.htm.

The average temperature and relative humidity for April in eastern North Dakota is about 40 degrees and 70 percent. The air will be warmed 3 to 5 degrees as it goes through fans being used for drying corn at a static pressure of 4 to 6 inches. After warming due to the fan, the air is about 45 degrees and relative humidity is about 60 percent. This air will dry corn to about 14 to 14.5 percent moisture.

This year, early April temperatures have been warmer and drier. The temperature is averaging about 45 degrees and the relative humidity is averaging about 60 percent.

If temperatures cool to an average of about 30 degrees, the fans can be stopped. Wait until the temperature again averages at least about 40 degrees before starting the fans. Cool the grain by operating the fans at night or other cool periods before shutting off the fans to extend the storage life of the grain.

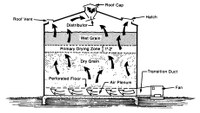

Some people are concerned about shutting fans off because that leaves a drying front in the grain. The drying front is the area in the grain mass where the drying is occurring. The dry air comes in contact with wet grain at the bottom of the drying zone, picks up moisture until it comes into equilibrium with the grain in the drying zone and then carries that moisture through the wet grain above the drying zone and out of the bin.

“There is nothing magical about the drying front or zone,” Hellevang says. “The grain and the drying zone will be in the same condition several days later when the fan is started again.”

Fans should be shut off when rain falls for more than a few hours and during fog. Drying is not occurring during these times, so the only benefit of operating the fans is to cool the grain. Some grain rewetting will occur if operating the fans during wet conditions. The fans can be started again when the air is drier.

Here are Hellevang’s recommendations for drying other crops:

Soybeans

Use an airflow rate of at least 1 cfm/bu to natural-air dry up to 16 percent moisture soybeans. The expected drying time with this airflow rate will be about 50 days. The allowable storage time for 18 percent moisture soybeans is only about 40 days at 50 degrees, so use a minimum airflow rate of 1.5 cfm/bu to natural-air dry 18 percent moisture soybeans.

Wheat

The air will be warmed about 5 degrees as it goes through fans being used to dry wheat at a static pressure of about 6 inches. After warming due to the fan, the average April air is about 45 degrees and relative humidity is about 60 percent. This will dry wheat to about 14 percent moisture.

May is typically warmer and drier than April, so wheat will dry to about 13 percent moisture by mid-May. The estimated time to dry 17 percent moisture wheat using an airflow rate of 0.75 cfm/bu is about 40 days at 47 F. Because this year’s air temperature has been warmer and the relative humidity lower, now is the time to start natural-air drying wheat.

Operating the fans during the warmer and drier daytime hours will permit drying the wheat to a lower moisture content. For example, if the temperature is 55 F and the relative humidity is 55 percent, the wheat will dry to about 13 percent moisture in about 30 days. However, if the warmer and drier air is obtained by operating the fans from 7 a.m. to 9 p.m., then drying the wheat will take about 50 days due to the reduced fan operation time each day.

Waiting until mid-April, when temperatures are warmer and the air is drier, to start drying wheat generally is advisable. Adding supplemental heat that warms the air 3 to 5 degrees permits drying at a higher humidity but will approximately double the cost of drying.

Barley

Malting barley germination will be lost if adequate airflow is not provided so the barley is dried within the allowable storage time. Drying occurs in a zone that moves from the bottom to the top of the bin if the air is pushed up through the barley. Grain at the top will stay near the initial moisture content until the drying zone reaches the top of the grain, so adequate airflow to dry the barley within its allowable storage time is critical.

The allowable storage time (or drying time) is related to the grain temperature and moisture content. The allowable storage time, based on germination, for 17 percent moisture barley is about 140 days at 50 degrees, 65 days at 60 degrees and 30 days at 70 degrees. Germination will be lost before mold growth is visible. An allowable storage time chart for malting barley is available at http://www.ag.ndsu.nodak.edu/abeng/postharvest.htm.

Allowable storage time is cumulative, so if the 17 percent moisture barley was stored for 60 days last fall at 50 degrees before it was cooled for winter storage, the allowable storage time this spring is only about 60 days at 50 degrees before germination is lost.

Drying 17 percent moisture barley will take about 40 days with an airflow rate of 0.75 cfm/bu at 50 degrees. Therefore, an airflow rate of 0.75 cfm/bu is the minimum recommended airflow rate to dry 17 percent moisture barley in the spring.

“Adding supplemental heat to a natural-air drying system will reduce the moisture content of the grain but only slightly reduces the drying time,” Hellevang says. “More airflow is required to increase the drying speed.”

Warming the air by 5 degrees will reduce the relative humidity by about 10 percent and the barley moisture content by about 1.5 percentage points. The air normally will be warmed 3 to 5 degrees by the fan operating at a static pressure of about 5 to 6 inches associated with drying barley, so typically, little additional heat is needed.

NDSU Agriculture Communication

| Source: | Ken Hellevang, (701) 231-7243, kenneth.hellevang@ndsu.edu |

|---|---|

| Editor: | Ellen Crawford, (701) 231-5391, ellen.crawford@ndsu.edu |