High-moisture Corn has Advantages, Disadvantages

(Click the image below to view a high-resolution image that can be downloaded)

High-moisture corn offers many advantages for people who feed beef or dairy cattle, according to a North Dakota State University livestock expert.

“However, successfully using high-moisture corn requires attention to storage conditions, feeding management and processing,” says Greg Lardy, NDSU Extension Service beef cattle specialist.

Corn can be harvested wet and stored as high-moisture corn. For corn to be used in this manner, it should be:

- Harvested at 24 percent to 33 percent moisture for optimum storage

- Stored in plastic silage bags or oxygen-limiting silos for best oxygen exclusion at 24 percent to 26 percent moisture

- Stored in bunker or trench silos or piled and packed into a pile on the ground at 26 percent to 33 percent moisture

All bunker, trench and pile structures should be covered with plastic. If no bunker is available, a pile can be constructed, but increased storage losses typically result. Lardy advises that for best results with piles, use a 2- to 3-foot ridge of soil as a barrier to facilitate the packing process.

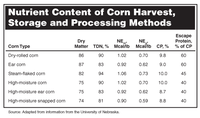

High-moisture corn is similar in energy and protein content to dry corn and offers several harvest advantages:

- Yields typically are increased due to less ear drop in the field.

- High-moisture corn allows for an earlier corn harvest, avoiding difficulties associated with adverse weather.

- No drying costs are encountered.

However, producers should realize that high-moisture corn also has some disadvantages, compared with dry corn, Lardy says. They include:

- Marketing alternatives are limited. High-moisture corn will be marketable only through livestock. Since high-moisture corn will undergo fermentation, it cannot be marketed in traditional channels for ethanol production or other uses.

- High-moisture corn may require additional storage and processing equipment.

- Improperly ensiled high-moisture corn will result in excessive spoilage and storage losses.

High-moisture corn tends to ferment faster and require better bunk management, compared with dry corn, so the high-moisture corn must be stored in an airtight silo (bunker, silage bags or oxygen-limiting structure). Lardy says. For optimum storage and utilization, it also should be processed (ground or rolled) prior to storage. Grinding or rolling and subsequent packing of the corn facilitates oxygen exclusion in the silo.

When pricing corn, producers should take into account differences in moisture level, particularly with high-moisture corn. Dry corn typically is traded at 15 percent moisture. High-moisture corn can have moisture levels from 24 percent to 33 percent, which necessitates adjustment to a constant moisture level.

NDSU Agriculture Communication

| Source: | Greg Lardy, (701) 231-7660, gregory.lardy@ndsu.edu |

|---|---|

| Editor: | Ellen Crawford, (701) 231-5391, ellen.crawford@ndsu.edu |