Heating Farm Shops (AE1620, Revised Feb. 2019)

Availability: Web only

Types of Shop Heaters

You have three basic options with variations for providing heat in a farm shop: forced air, infrared radiant and in-floor heating systems.

- Forced air heaters generally are installed near the ceiling and burn a fuel source to heat air, which then is circulated throughout the shop (Figure 1).

- Infrared heaters hang from the ceiling and heat the objects exposed to the heater. They often are used for spot heating areas such as a workbench but can heat the entire shop (Figure 2).

- In-floor heating uses hydronic piping (floor heat) embedded in or below the floor to provide heat (Figure 3). Heat is provided from a boiler or ground source heat pump (geothermal). These systems often are preferred because the heated floor provides a warm surface to stand on and water on the floor dries rapidly.

Figure 1. Forced-air propane furnace. (Carl Pedersen, NDSU)

Figure 2. Radiant heater. (Courtesy of www.USDA.gov)

Figure 3. In-floor hydronic tubing. (Carl Pedersen, NDSU)

What is a Btu?

A Btu, or British thermal unit, is a measure of heat. Btu per hour is the heating or cooling capacity of a heating appliance or air conditioner. One Btu is about the amount of energy needed to heat a pint of water 1 degree Fahrenheit.

Proper Sizing

Deciding on what size heating system to buy for a farm shop will depend on the size of the shop, how the shop will be used, how well it is insulated and how often the large doors will be open.

The construction of a building makes a huge difference in how much heat the heating system needs to deliver. Just a few years ago, a general rule of thumb was that farm shop heating systems should provide around 50 Btu per square foot per hour. With advances in insulating techniques, including more attention to air sealing and foundation insulation, farm shops commonly need only 20 Btu per square foot per hour.

While using generalizations for simple heating system comparisons is fine, you need to do heat loss calculations to properly size a farm shop heater. With a true heat loss calculation, you can install the properly sized heating system, which will ensure you get the proper amount of heat from the installed system and save you money by not having a heating system that is too large for the space you want to heat. A good heating contractor not only will do a heat loss calculation but also will provide guidance on the need for backup heating systems.

Putting different areas of the farm shop on various zones in which heat can be controlled separately can result in energy savings. If different areas of the shop are to be heated at different levels, you would need to make adjustments to the Btu per hour (for example, if the shop area is heated to 50 F and an office included in the building is heated to 72 F).

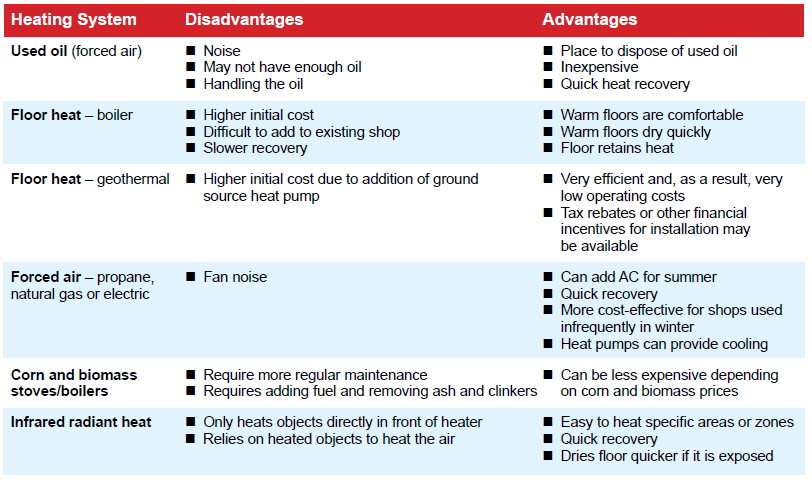

Advantages/Disadvantages of Common Systems

Heating Costs

Typical energy sources for farm shops are propane, electricity, fuel oil, and biomass such as corn or wood. Deciding which fuel source is most cost-effective depends on the current and future fuel prices, including off-peak electricity rates, the efficiency of the heating system and the amount of energy each heating system will require.

NDSU Extension has a publication and a mobile device app titled “NDSU Fuel Cost Comparison” that can help you compare various fuel sources. The app is available at mobile device application stores for Android and Apple.

Insulation

Insulating properly is just as important, if not more important, as choosing a heating system that will work well to ensure a comfortable and efficient building.

Heat will find the path of least resistance to escape a building. If one portion of the building is not air sealed (Figure 4) or insulated properly, the result will be wasted heat and wasted money during the entire life of the building.

Figure 4. Air leaks resulting in wasted heat. (Carl Pedersen, NDSU)

Heat loss will occur through the ceilings, walls and the floor. With proper insulation, that heat loss can be minimized and the insulation will pay for itself in energy savings in just a few years.

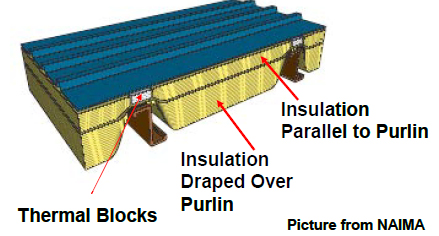

For cost-effective insulation levels in Northern climates, heating experts recommend you have at least an R-30 value in ceilings if the insulation is continuous insulation over the roof deck (Figure 5). For metal buildings (Figure 6), a standard recommendation is to have insulation installed to a value of at least an R-25 draped over the purlins. Also, there should be an additional R-11 parallel to the purlins, and the roof deck and purlins separated by R-5 thermal blocks. An R-49 should be installed for roofs with attics or other insulation applications.

Figure 5. Continuous insulation on roof deck. (Courtesy of U.S. Department of Energy building codes university)

Figure 6. Insulated metal roof. (Courtesy of North American Insulation Manufacturers Association and U.S. Department of Energy building codes university)

Walls in the shop should be insulated to at least an R-13 between framing members, with continuous insulation to at least an R-7.5.

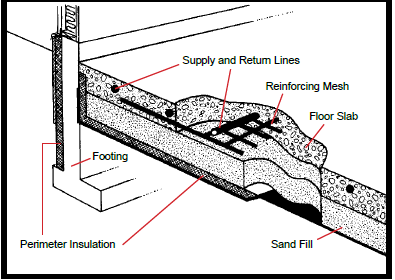

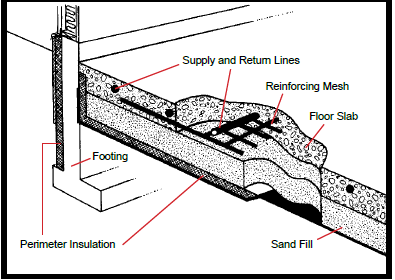

Perimeter foundation footings should be insulated to at least an R-10, with an additional R-5 added if the slab is heated (Figure 7). The insulation should extend at least 24 inches below an unheated slab and at least 48 inches below a heated slab.

Figure 7. Frost protected shallow footing foundation for heated slab. (Courtesy of Larry Mayer, Solution Design Inc.)

Heat loss from the perimeter of a slab hydronic heated building can be huge. The soil around the perimeter is continually being cooled by the outdoor air, so insulating the perimeter is critical. Insulation under the concrete slab will reduce the rate of heat flow into the soil and direct more of the heat into the shop. Insulation is generally not used under the floor if the soil is used as a heat reservoir. A high water table can transfer heat away from under the floor. Hydronic tubing can be either placed in the concrete or in a sand bed below the concrete (Figure 8).

Figure 8. Hydronic floor and space heating.

Ground-source Heat Pumps (Geothermal)

Ground-source heat pumps, often referred to as geothermal, are one option for heating farm shops as a result of the high efficiency of the systems. Heat pumps heat or cool a building by moving heat from one location to another. While ground-source systems are very efficient, they have a higher installation cost.

Ground-source heating systems generally require three main components (Figure 9): the heat exchanger (ground loop), a heat pump (condensing unit) and a distribution system such as in-floor tubing (Figure 3).

Figure 9. Components of ground source heating system. (NDSU Extension)

The heat exchanger or loop (Figure 10) is simply a length or coil of tubing placed underground and used to transfer the heat from the ground to the heat pump.

Figure 10. Loops for ground source heat pump. (Dennis Wiesenborn, NDSU)

The heat pump concentrates the heat using a condensing unit. In the winter, that heat is transferred to the distribution system and released through the building’s forced-air systems or in-floor hot water (hydronic) heating system.

For more information on ground source heat pumps, consult the NDSU Extension publication AE-1483, “Ground-source Heat Pumps.”

Additional Resources

Variety of energy-related information

AE-1483, “Ground-source Heat Pumps,” NDSU Extension publication covering the basics of heat with ground source heat pumps.

Majority of publication written by Carl Pederson former Energy Educator

Special thanks to Sheldon Gerhardt, Logan County Extension agent, NDSU, and Randy Mathern of Comfort Zone Heating and Air for providing technical reviews.

This material is based upon work supported by the Department of Energy under Award Number DE-FG26-07NT43202.

This report was prepared as an account of work sponsored by an agency of the United States Government. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply it endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.