Increasing Food Safety on the Farm with Good Agricultural Practices (FN1920, May 2019)

Visit www.ag.ndsu.edu/fieldtofork for educational modules and more information about topics covered in this manual.

Purpose of this Manual

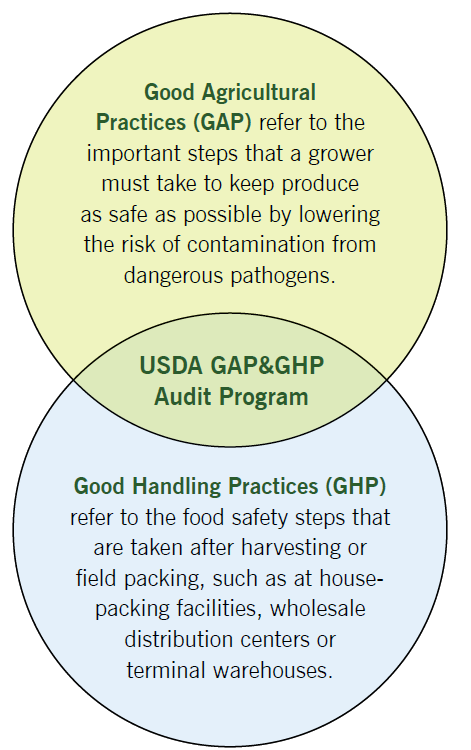

Small-farm operators may see the food safety certification process as a roadblock to getting their fresh produce into food service, institutional and retail markets. This manual assists specialty crop growers who have an interest in increasing food safety on their farm, documenting good agricultural practices, or becoming certified through the USDA’s Good Agricultural Practices and Good Handling Practices (GAP&GHP) audit verification program. Our goal is to help you understand the GAP&GHP audit cycle (before, during and after an audit) and identify potential benefits of becoming certified. The GAP portion of the audit pertains to on-farm production and harvesting practices, while the GHP portion of the audit covers the packing, storage and distribution of crops. This manual covers the GAP sections of the USDA audit verification program and does not cover the GHP sections.

You will benefit from this manual if you:

- Are a specialty crops grower.

- Would like to make your food safer for consumption.

- Want to learn more about GAP and GHP certification and how it might benefit you.

- Would like to market your products with buyers who require you to have certification.

- Want to know how to develop, document and implement a food safety plan.

This manual does not guarantee a successful USDA GAP&GHP audit. The success or failure of an audit is determined by how well you have identified and addressed the food safety risks around and within your farming operation. As we walk through the Audit Certification Checklist (in Section 5, page 33), we will point to the kinds of risks you should consider when tailoring a food safety plan for your farm. Throughout this guide, we identify how auditors use the checklist when inspecting farm operations. A better understanding of what auditors look for may help you pinpoint ways to become better prepared for the USDA GAP&GHP certification process.

This manual provides a general background on the USDA Agricultural Marketing Service GAP&GHP audit verification program. We provide content and examples to help you interpret the program’s requirements and demonstrate how audit items are scored so you may prepare when developing, implementing and maintaining your operation’s food safety program. This manual draws from content found in government agency publications:

- Food and Drug Administration (FDA) Guide to Minimize Microbial Food Safety Hazards for Fresh Fruit and Vegetables (dated October 1998)

- USDA Good Agricultural Practices Good Handling Practices Audit Verification Checklist (dated Sept. 18, 2014)

- USDA User’s Guide for GAP&GHP (dated April 2011)

- USDA Audit Instructions for GAP&GHP (dated November 2009)

Consider drafting your farm policies, standard operating procedures (SOPs) and corrective action plans while you work through this manual. Such documents will come in handy as you develop a food safety plan, whether your goal is to prepare for a USDA GAP&GHP certification audit or you simply want to implement the best practices possible for your farm operation.

We thank the following technical experts for their review of this manual:

Kim Butz

Local Produce Safety Coordinator

Carolina Farm Stewardship Association

P.O. Box 448

Pittsboro, NC 27312

Emily Griep, Ph.D.

Manager, Food Safety

United Fresh Produce Association

1901 Pennsylvania Ave. N.W. No. 1100

Washington, DC 20006

Background

Specialty crops are defined as “fruits and vegetables, tree nuts, dried fruits, horticulture and nursery crops (including floriculture).”2

The Agricultural Marketing Service1 (AMS) Specialty Crops (SC) Program helps specialty crop growers and handlers combine available resources to grow their respective industries and overcome marketing barriers. To do this, the AMS created strategic partnerships with state agencies and organizations for the benefit of growers, shippers, brokers, receivers, processors, retailers, restaurants, direct-to-consumer salespeople and the food service industry nationwide.

In the AMS Specialty Crops program, you will find a wide array of services, ranging from helping to market the quality of your products to ensuring that you experience fair trade in the produce industry. The USDA’s GAP&GHP audit verification program is a voluntary, market-access solution offered to the specialty crops industry.

In October 1998, the USDA and the U.S. Food and Drug Administration (FDA)3 issued guidance documents to the fresh fruit and vegetable industry for reducing microbial contamination of fresh produce meant for human consumption. The FDA’s “Guide to Minimize Microbial Safety Hazards for Fresh Fruits and Vegetables” (the FDA guide) included a number of recommendations for following Good Agricultural Practices (GAP) and Good Handling Practices (GHP). Soon after, many wholesale produce companies and food-service buyers of fresh fruits and vegetables began to require that their suppliers undergo third-party audits to verify supplier adherence to the FDA’s GAP and GHP recommendations.

To address numerous requests from the fruit and vegetable industry, the USDA AMS, in cooperation with the Association of Fruit and Vegetable Inspection and Standardization Agencies (AFVISA), developed an audit-based program to verify suppliers’ conformance with the FDA guide. In August 2001, the USDA tested and approved a draft of the auditor checklist to satisfy the needs of growers and shippers. In January 2002, the USDA formally implemented the GAP&GHP audit verification program as a nationally recognized market-access tool that applies uniformly to the U.S. fresh produce industry.

The GAP&GHP program is a voluntary and user-fee funded program. Scheduled audits are intended to occur at least once per year to verify that a supplier’s crop(s) (e.g., fresh fruits and vegetables) have been produced, packed, handled and stored as safely as possible to minimize risks of microbial food safety hazards. The audit program does not guarantee that a supplier’s product is free from microbial contamination. Rather, the program verifies the extent that an audit participant has taken proactive measures to reduce risk of product contamination by adhering to generally recognized best practices. Continued observance of GAP&GHP best practices and responsibility of product safety remain with the operation in charge of producing and handling fresh products.

Adhering to generally recognized food safety best practices is not a new concept for many farming operations. However, the implication of fresh produce in major foodborne illness outbreaks in the U.S. has prompted buyers and suppliers to embrace a more proactive (rather than reactive) approach that protects the safety and well-being of consumers and minimizes the industry’s economic impact of food recalls stemming from foodborne illness outbreaks.

Market-Access Considerations

Many growers seek an audit to meet the requirements of particular buyers or a new market that requires third-party food safety certification. The USDA GAP&GHP audit verification program can be structured to meet your buyers’ requirements. Attaining certification may open new markets, such as schools, major retail grocery stores or wholesalers, for your products. Your current (or new) buyers may require that you pass the food safety audit before they will purchase your products.

If an existing or potential customer asks you for GAP certification, understand the customer’s needs and concerns. Which GAP audit sections are required to address those concerns? In the case of farm-to-school customers, is there a particular distributor already certified to serve the local school district? Will the school approve your products if delivered through that distributor? Depending on your operation and market-access needs, particular audit sections may be more or less cost-effective for you to perform. For example, Part 1 (Farm Review) and/or Part 2 (Field Harvest and Field Packing) may be more approachable for farms just getting started with food safety certification.

Tip for Audit Selection: Some buyers only will accept GAP certification from a private certifier. Identify which certifying agency your buyers prefer before investing time and resources into audit Services.

Audit Scopes

The USDA’s audit verification program is divided into seven sections, called scopes. As seen in Table 1, each scope covers specific aspects of the food supply chain. The USDA considers a GAP audit to consist of Parts 1 (Farm Review) and 2 (Field Harvesting and Field Packing Activities). A GHP audit consists of Parts 3 and 4 (for pre-farm gate operations) and Part 6 (for post-gate operations). Part 7 is an optional scope if you need verification of a food defense plan. With the exception of only conducting a Food Defense Audit (Part 7), the General Questions scope is required for every audit that takes place on your farm, regardless of buyer expectations. When planning your audit, identify which scopes to include.

Table 1.Scopes of GAP and GHP Audit Program

|

GAP |

GHP |

Audit Scopes |

|

X |

X |

General Questions |

|

X |

Part 1 – Farm Review |

|

|

X |

Part 2 – Field Harvesting and Field Packing Activities |

|

|

X |

Part 3 – House Packing Facility |

|

|

X |

Part 4 – Storage and Transportation |

|

|

N/A |

N/A |

Part 5 - (no longer used) |

|

X |

Part 6 – Wholesale Distribution Center/Terminal Warehouse |

|

|

Opt |

Opt |

Part 7 – Preventative Food Defense Procedures |

Onsite visits allow an auditor to observe and verify that you are implementing good agricultural and handling practices throughout your operation. For a Part 1 review, the auditor must visit and evaluate your operation while your crops are actively growing. For a Part 2 review, the auditor must observe your harvesting and packing activities. Depending on the size of your operation and the audit scope(s) requested, the auditor may need to make several trips to your location to conduct the initial audit. For example, the auditor may complete the farm review section on the first visit and the packing house section on a second visit.

Certification

For each GAP&GHP audit that you request (see page 19), you will have a unique audit verification program scoresheet. The auditor will use the scoresheet to summarize the evaluation of scopes under review. The summary will include the date and time that your audit began, as well as the date and time that the audit was completed. The auditor will note your pass-fail status for each scope and corresponding scores.

Audit Scopes Covered on the Same Day

Some audits can be performed on a single day’s visit. Of course, this is dependent on the type of scopes identified in the audit request and the complexity of the operation under review, including the number of days in operation and the commodities to be audited. If your GAP&GHP audit is completed without fail in a single day, the auditor will finalize the audit scoresheet by indicating “All Scopes Completed” and move the certification process forward by submitting the scoresheet to the appropriate reviewing official (e.g., supervisor). If approved at this level, the official will sign and forward your scoresheet to the USDA Branch’s Audit Program Coordinator (APC). In turn, the APC will generate your USDA certificate for the commodities covered in your audit.

Audit Scopes Covered Across Time Periods

If the auditor determines that additional visits to your location (e.g., announced and/or unannounced) are necessary to complete the entire audit process, the scoresheet and corresponding audit report will remain a work in progress. All detail collected by the auditor during subsequent visits will be added to the relevant scope sections of the scoresheet. As the scopes are completed during subsequent visits, the auditor will forward your scoresheet information to the appropriate reviewing official (e.g., supervisor) for a review and signature. This process will be repeated until all scopes have been covered across your audit period.

Once the entire GAP&GHP audit is completed without fail, the auditor will finalize your scoresheet by indicating “All Scopes Completed” and move the certification process forward following the same procedures described in the single-day audit. The auditor will submit your information to the appropriate reviewing official (e.g., supervisor). If approved at this level, the official will sign and forward your scoresheet to the USDA Branch’s Audit Program Coordinator (APC). In turn, the APC will generate your USDA certificate for the commodities covered in your audit.

For same-day and multiday audits, the certificate is specific to commodities covered in your requested audit and will be good for one year from the initial audit date. Your information pertaining to the completion of audits (for Parts 1 through 6 only) that meet USDA GAP&GHP criteria will be posted on the USDA website and will remain there for one year, unless you fail an unannounced verification visit in the meantime. (See Table 2, p. 6, for USDA excerpt of information posted.)

Audit Reports on Websites

The USDA Specialty Crops Inspection (SCI) Division can upload your USDA audit report to one or more commercial supply chain databases: ICIX, Azzule Systems or Food LogiQ. SCI charges one hour at the current audit rate ($108/hour) per each upload for each system that you choose.

You must pay the bill for the upload to maintain your certification listing on the USDA website.

Upload Options – Links to External Sites

- ICIX: https://www.icix.com

- Azzule Systems: http://www.azzule.com/

- Food LogiQ: https://www.foodlogiq.com/

General Auditor Policies

All USDA GAP&GHP auditors are either federal USDA AMS employees or state department of agriculture employees who have been specifically trained and licensed to conduct audits on behalf of the USDA AMS. Many of these licensed individuals are fruit and vegetable inspectors who grade produce on a daily basis. Individuals licensed by the USDA AMS use the GAP&GHP audit checklist to assess your operation. The USDA auditors are prohibited from performing a desk audit of another auditing firm’s results as verification of your conformance to the USDA GAP&GHP audit checklist. Additional information and the current USDA GAP&GHP checklist can be found at www.ams.usda.gov/gapghp.

USDA AMS policy states individuals licensed to perform GAP&GHP verification audits have no financial interest in the operations that they observe and products that they audit. This policy is in place to maintain the unbiased nature of the audit services and avoid any potential conflicts of interest. To remain impartial, the USDA auditors are prohibited from providing any form of consulting services to potential auditees. This means that the auditor is unable to offer recommendations specific to your operation on how you can conform to any questions on the GAP&GHP audit checklist. For example, the USDA auditor is not allowed to tell you how to write a food safety program for your operation or which actions you need to take to improve compliance with USDA program requirements and increase your audit score. When you have such questions, the auditors are obligated to direct your inquiries to food safety experts, such as Extension specialists. Contact the N.D. Department of Agriculture for assistance.

Table 2. Excerpt of Information Posted on USDA Website for Companies Meeting GAP&GHP Acceptance Criteria.

|

Company |

Address |

City, State |

Scope(s) of Audit Conducted |

Date Audit |

Commodities Covered by Audit |

|

Audit Type: USDA Good Agricultural Practices and Good Handling Practices Audit |

|||||

|

Commodity: Onions |

|||||

|

Location: North Dakota |

|||||

|

Benz Farm LLP |

519 5th Ave. S.W. |

Steele, N.D. |

Farm Review, Field Harvesting and Field Packing Activities, Storage and Transportation |

Oct. 2, 2018 |

Onions |

|

Commodity: Potatoes |

|||||

|

Location: North Dakota |

|||||

|

Bill Sheldon |

11028 51st St. N.W. |

Ray, N.D. |

Farm Review, Field Harvesting and Field Packing Activities, Storage and Transportation |

Aug. 30, 2018 |

Potatoes |

|

OC Schulz and Sons |

401 4th St. |

Crystal, N.D. |

House Packing Facility, Storage and Transportation |

Feb. 28, 2019 |

Potatoes |

Note: Report Name: G01 - By Audit Type Commodity Location and Company Name - Auditees that Meet Acceptance Criteria; Print date: 3/29/2019 9:18:57 AM. This excerpt shows variations in scopes and commodities for three of 44 North Dakota companies listed on the USDA website. For a complete and current list go to https://apps.ams.usda.gov/GAPGHP/reportG01.aspx.

Appeals, Complaints and Disputes

You have the ability to appeal, dispute or lodge a complaint regarding a USDA GAP&GHP audit or the individual licensed to perform the audit.

- Appeal: The USDA defines an appeal as a formal complaint contesting the results or findings of an audit brought before the Fresh Products Branch (the Branch) by applicants or other parties.

- Complaint: The USDA defines a complaint as discontent or unhappiness about a situation, interpretation or performance of an audit, auditor(s) and/or policy brought before the Branch by applicants or other parties.

- Dispute: The USDA defines a dispute as a disagreement or argument about a situation, interpretation or performance of an audit, auditor(s) and/or policy brought before the Branch by applicants or other parties.

Appeals, complaints and disputes must be submitted to the Branch within three calendar days from the date the audit service was performed.

Your formal request for appeal must be in writing and on your company letterhead. Your request must include the audit date, the location of the audit and the sections of the original audit being appealed, with clear identification of specific items under dispute.

Your appeal will be reviewed by the USDA Audit Review Board (ARB) authorized to sustain or reverse your appeal. The ARB will consist of a minimum of three members designated by the Branch chief. Members will be Branch headquarters staff (e.g., federal program managers) with good standing as audit program evaluators.

The ARB meets as needed to review audit appeals, and provides results of an appeal to all parties involved in the appeal process within 14 calendar days. Copies of your appeal and the ARB results will become a permanent part of your audit record.

Direct complaints regarding Branch policies and procedures to the Audit Management Section.

Complaints regarding an individual performing your audit should be directed to the auditor’s supervisor.

The Branch retains records of all appeals, complaints, disputes and subsequent actions taken that pertain to GAP&GHP audits. Additionally, the branch reviews and evaluates the effectiveness of all appeals, complaints, disputes and subsequent actions on a regular basis.

USDA

1400 Independence Ave. S.W.

Stop 0247

Washington, DC 20250-0247

Audit Costs

You will incur expenses each time the auditor needs to prepare for an audit and observe your operation for certification purposes. Your audit charges will include an administration fee. You will be charged for the auditor’s time, including time spent reviewing your food safety manual (in preparation for your audit) and travel time to and from your farm and actual time spent at your farm (to observe your operation). The expenses for follow-up visits to your farm will be charged in a similar manner to cover the auditor’s administration fees, prep time, travel time and time on the farm to conduct the follow-up inspection. It is possible that the auditor’s second unannounced visit will be smaller in scope, where the focus is on field operations and a review of your logs and records. As evidenced in Table 3, the auditor’s time has a significant impact on your bill.

Table 3. Example of May 2019 audit estimates.

|

Expense Type |

Time |

Charge |

|

Administration fees |

$ 50 |

|

|

Preparation time |

1 hour |

$ 108 |

|

Travel time to farm |

3 hours |

$ 324 |

|

Audit day time |

2.5 hours |

$ 270 |

|

Travel time from farm |

3 hours |

$ 324 |

|

Paperwork |

1 hour |

$ 108 |

|

Total Cost |

$ 1,184 |

Consider organizing your food safety manual, including SOPs and supporting documents, in the order of the GAP audit checklist. During the audit, the inspector will follow the USDA checklist. If your documents are organized in the same order, it may help your audit go more smoothly and quickly, and, in turn, save you money since audits are charged by the hour.

You are the best advocate for your operation. Prepare well for the audit and help the auditor realize that only one inspection may be necessary. Show as many crop production examples as possible during a single audit visit and help the auditor understand your processes. For example, hand harvesting tomatoes may satisfy the auditor’s need to see the harvest of other vegetables that are not grown in contact with soils that you also hand harvest.

To save money, try to coordinate your audit when others in the area may need an inspection. Perhaps you can request your audit for the same or subsequent day and share in the cost of the auditor’s travel time. To find others interested in coordinating audits, check with neighbors, ask operators at the farmers market, ask buyers or seek out university Extension agents. An auditor will divide the travel costs between farms if multiple (and nearby) sites can be audited during a single trip to your area.

Cost Savings Tips:

- Follow the USDA GAP&GHP audit checklist to organize your food safety manual and supporting documents to help your audit go smoothing and quickly.

- Prepare well for the audit and help the auditor see why only one inspection may be necessary.

- Try to coordinate audit dates with others in your area to share in auditor travel fees.

Your Food Safety Program

Establishing and implementing a food safety program is highly recommended for any operation responsible for producing and handling fresh fruits and vegetables, not just for those wishing to participate in the USDA GAP&GHP audit verification program. During a GAP&GHP audit, you will be asked to explain and demonstrate how your operation complies with industry best practices and more specifically the FDA’s recommendations for minimizing microbial safety hazards for fresh fruits and vegetables. Before you can participate in the USDA GAP&GHP audit verification program, you are required to develop and implement a documented food safety program that applies specifically to your operation.

Food Safety Manual

Normally, a food safety program takes the form of a written manual that (a) details all aspects of the growing and handling processes; (b) identifies potential sources of risk of microbial, physical and chemical hazards; (c) outlines specific, measureable steps necessary to reduce the risk of product contamination; and (d) describes steps that you have taken when product contamination has been suspected or realized.

Consider three main steps as you start to assemble your food safety manual.

First, write a mission or vision statement that captures your operation’s commitment to food safety, food quality, food sanitation, and worker health and hygiene. Write your statement in a brief, general yet thorough manner to adequately describe the extent that you and your employees embrace your food safety program. Place the statement at the front of your manual. An example of a mission statement might be:

Management and employees of Specialty Crops Incorporated are committed to producing and marketing the safest products possible through the implementation of good agricultural and handling practices that focus on the principles of food safety and quality.

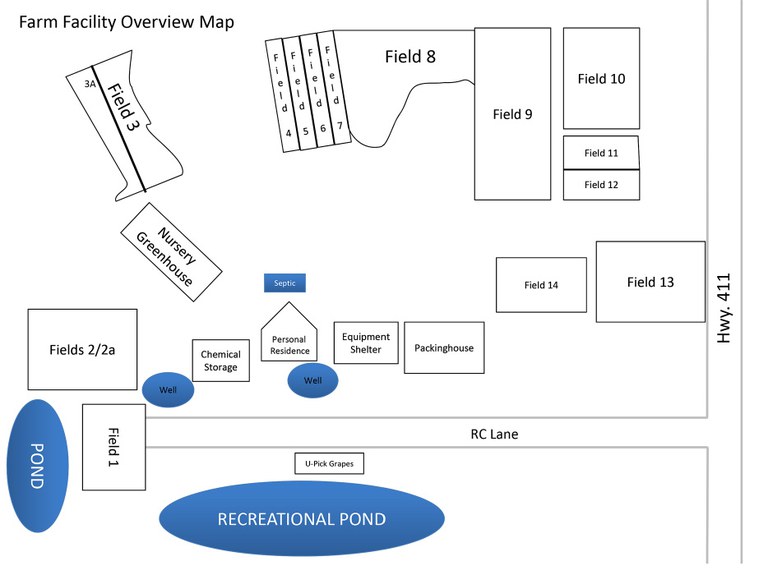

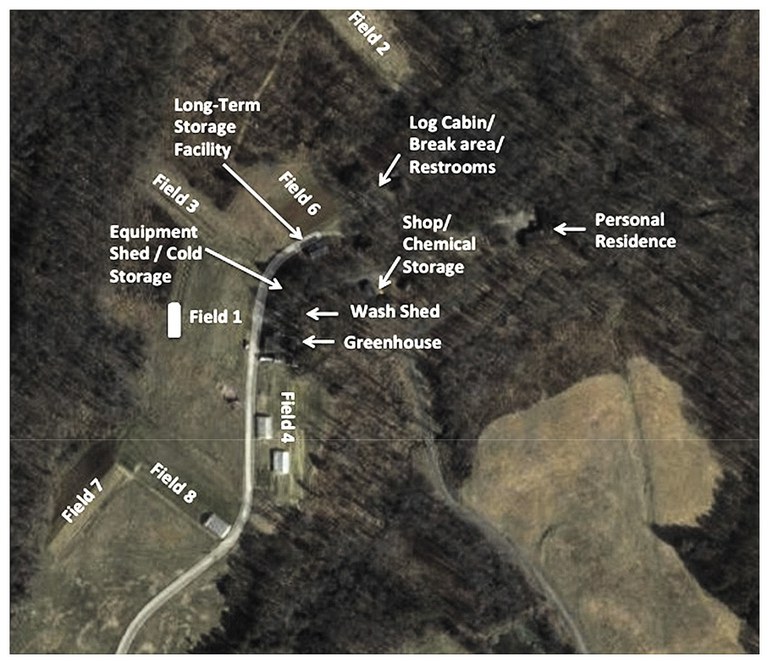

After writing your mission statement, write a description of your farming operation. Describe the physical location of your operation, all the acres that you farm (whether owned, leased, rented, contracted or consigned), where all your production areas are located (including primary and secondary locations) and the various crops that you grow. If you have a packing house facility, include a floor plan to indicate the flow of product (e.g., entering and leaving the storage areas), areas where products may be commingled or culled, employee breakrooms, restrooms, offices, and where pest control devices and water lines are located. Include maps of your farm fields to show surrounding irrigation sources, hydrants and other details. Sketch out a corresponding map of your farm and insert it after your written descriptions. For farm map examples, see Figure 2 (p.12) and Figure 3 (p.13)

Second, create a table of contents that corresponds to the audit scopes that will pertain to your operation. (Refer to the audit scopes in Table 1, p. 4.)

Third, write in detail how each of the GAP&GHP audit scopes pertains to your operation. As you describe a scope, provide detail about how your operation is complying with the requirements of that audit scope. Insert copies of the related standard operating procedures (SOPs) and include examples of corresponding documents and forms that pertain to the scope you are writing about.

The key to developing a well-written plan is to include applicable documentation that will prove to an auditor that you have an established food safety program in place. Your written manual also may contain information or references pertaining to management reviews of your food safety program or any self-audits that have been conducted to test the program’s effectiveness.

Food Safety Officer

If your operation is serious about following a food safety program, designate an individual with sufficient food safety knowledge to ensure that the program is being followed. Whether the designated individual (e.g., food safety officer) is you, a cooperator or some other person on staff, you must name the individual in your food safety manual (e.g., use an organizational chart or some similar documentation). In this manual, we use the term “food safety officer,” although your organization may use a different title (e.g., manager, supervisor, etc.).

The food safety officer needs to comprehend all elements of the operation’s food safety practices, right down to the details provided in the food safety manual. You and your food safety officer need to be readily available to answer auditor questions whenever your operation undergoes any form of the USDA GAP&GHP audit. In preparation for an audit, it is vital that the two of you (a) determine what to document in your food safety manual (based on the GAP audit checklist); (b) maintain current and accurate records that reflect your farm’s adherence to policies and procedures stipulated in the manual; and (c) document any corrective actions that have been taken to adjust your food safety plan.

Establishing, implementing and maintaining an effective food safety plan involves the evaluation

of many processes. Find links to numerous

resources on the USDA GAP&GHP website

www.ams.usda.gov/gapghp. State and federal agencies, university and Extension programs, and trade and commodity associations offer additional guidance for food safety planning.

Tips for Building your Food Safety Program

Be sure your food safety manual includes:

- Your food safety mission statement

- The name of your designated food safety

officer- Records to show any completed GAP&GHP trainings

- A map that accurately represents your farm and shows all growing areas.(See examples, Figure 2, Figure 3)

- Legal descriptions (e.g., county-issued parcel number)

- Locations of all production areas (also secondary parcels)

- Total number of acres farmed

- Locations of all packing facilities

- Packing facility floor plans (show product flow, storage areas, cull areas, employee breakrooms and bathrooms, offices, etc.)

- Documents pertaining to commingled product (from different growers) that occurs at your farm

- Food safety practices that are relevant to your farm and can be fully implemented

- Written SOPs that define policies and procedures you and your staff follow to carry out the plan

- Written logs of your farm’s activities, including training practices, water test results, mock recalls, etc.

- Figure 2. Farm Map Example 1. Image used with permission from North Carolina Farm Stewardship Association. www.carolinafarmsteadstewards.org

- Figure 3. Farm Map Example 2. Image used with permission from North Carolina Farm Stewardship Association. www.carolinafarmstewards.org

Record Keeping

Your operation’s records are key components of your food safety plan. Since the auditor is not at your operation on a daily basis, your records provide evidence that you have policies and procedures in place and that you have completed certain tasks throughout the year to maintain a consistent level of conformity to your food safety program. Understand the difference between the documentation requirements so that you will be prepared when the auditor asks to review your items during the audit. If you plan to participate in the USDA verification program, the GAP&GHP audit checklist defines three types of documentation that are required of your operation.

As seen in Figure 4, the documentation requirements are identified in the far right “Doc” column of the GAP&GHP audit checklist. A letter “P” in the checklist “Doc” column indicates that a policy/standard operating procedure (SOP) must be established and documented in your food safety plan to explain what you will do to conform to a particular audit question requirement. A letter “R” in the “Doc” column indicates that you must keep records to prove that an action or process has been completed. Records may take the form of schedules, work logs, checklists, service records, billing forms, service contracts, water test results, etc. A record is your written verification that shows when, why, how and by whom a specific task or procedure has been done.

Figure 4. Excerpt from the USDA GAP&GHP Audit Checklist for Worker Health and Hygiene.

|

Worker Health and Hygiene Questions |

||||||

|

Questions |

Points |

Yes |

NO |

N/A |

Doc |

|

|

G-3 |

Potable water is available to all workers. |

10 |

R |

|||

|

G-4 |

All employees and all visitors to the location are required to follow proper sanitation and hygiene practices. |

10 |

P |

|||

|

G-5 |

Training on proper sanitation and hygiene practices |

15 |

D |

|||

|

G-6 |

Employees and visitors are following good hygiene/ |

15 |

||||

|

G-7 |

Employees who handle or package produce are washing |

15 |

||||

|

Note: The abbreviations (D,P,R) identify your documentation requirements for an audit |

||||||

A letter “D” in the “Doc” column means that you must keep a combination of SOPs outlining your company policies as well as records indicating that a particular action was taken. At minimum, you must keep and coordinate the relevant documentation for the questions identified with a “P,” “R” or “D” in the “Doc” column, although you may find it important (if not necessary) to keep additional documentation beyond what the USDA requires. The bottom line is that you must maintain sufficient records to show adherence to your food safety program as well as to USDA GAP&GHP requirements, and local, state and federal regulations. (See the hypothetical example of record keeping below)

Hypothetical Example of On-Farm Record Keeping

All farms requesting an audit of "Field Harvest and Packing Activities" must have a written policy (in the SOPs) that documents the preharvest assessment and must maintain records to prove that the assessment has been completed as specified. The assessment should include a review for evidence of crop damage or intrusion caused by domesticated or wild animals.

Scenario

- The Problem: The preharvest assessment ( or other field review) for your farm indicates a threat to your tomato and strawberry crops from excessive animal intrusions. The deer have been eating the leaves and fruit of the tomato plants. You have notices oblong, pellet-like droppings and deer tracks in the tomato production area. Your tomato fields are adjacent to you strawberry production areas, where you have found evidence of racoon droppings. Fencing the fields is not an option because deer can jump and racoons can climb.

- The Solution: To deter the deer, you mount solar-powered, motion-activated lights on movable stands and place them around the tomato production area, along with some white flags about the size and shape of a deer tail (10 inches long, 5 inches wide). When the deer see movement, your hope is that they will get spooked and flee. To deter the racoons, you place solar-powered predator deterrent lights throughout the strawberry field as well. The lights come on when night falls and stay on until daybreak. The lights flash and mimic the eyes of other animals, which should trigger the flight response in the racoons. You plan to monitor the fields regularly and move the deterrent devices around to maintain the element of surprise for the animal intruders.

For GAP's record-keeping (R) requirements, you must keep a written log that documents the placement of the flags and lights in the fields, tracks your ongoing monitoring efforts, and details any further crop damage and intrusions. The auditor will review your log during your audit. Your records (e.g., crop maintenance reports or field logs) should clearly document: (a) that your trained staff is monitoring the implemented solution for effectiveness, (b) any changes you or your staff have made based on observations, and (c) any corrective actions taken when the best practice strategies have proven ineffective. For example, your farm workers should be trained to: (a) make sure the white flags and solar lights are in place and not blown over by a storm; (b) monitor the crops for animal droppings and indications of eaten plants and fruit; (c) put red flags at every site location that displays evidence of intrusion (including animal droppings). In turn, all harvest crews should be trained to avoid harvesting any products within a 5-food diameter of any red flag. Your written log also should include all efforts to train the staff for this issue.

Test Your Food Safety Program

Although not a requirement of the GAP&GHP audit verification program, your operation should conduct a self-audit prior to scheduling your USDA audit. You can utilize the USDA GAP&GHP audit checklist to perform an internal audit of your operation. A self-audit provides the opportunity to identify challenge areas, make improvements, modify SOPs if necessary and take corrective actions before you undergo the USDA audit.

If you plan to participate in the USDA GAP&GHP audit program, there are advantages for testing and evaluating your food safety program as close as possible to the beginning of your growing season. You will have more time to accumulate documents and records that will be needed for the auditor to review while he or she performs your audit. You may run into a situation where you need to change policies and procedures to improve the efficacy of your food safety program (e.g., need to implement a procedure to reduce wild animal intrusions in a new crop production area). Once the growing season is underway, you may have limited time and resources to develop and fully implement a viable food safety program for your operation. Many growers take advantage of the winter season while the fields are less busy and start planning for their first-time audit to take place during the upcoming harvest.

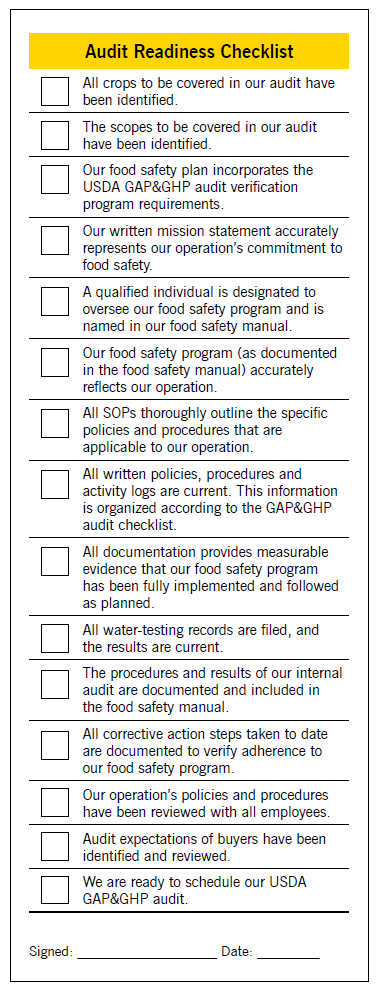

Create and complete a checklist (see Figure 6) to determine your operation’s readiness for scheduling an audit. File the checklist in your food safety manual, next to your audit request form.

- Figure 6. Audit Readiness Checklist. Figure developed by Kimberly Beauchamp, March 2019.

Required USDA Forms

Vendor Account Agreement

Prior to scheduling an audit, set up (or update) your vendor account with the USDA Specialty Crops Inspection (SCI) Division. The USDA will not bill you for services until after certification or audit documentation is completed. However, failure to establish an account or pay the bill may result in the cancellation of your USDA audit certification. You may submit the completed form (SC-430) to the USDA SCI Division using any of the following options:

- Email: SCRimbursement@ams.usda.gov

- Fax: 866-230-9168

- Mail: USDA, AMS, SCI, ASB

1400 Independence Ave. S.W.

Stop 0247, Room 0707-S

Washington, DC 20250-0247

Form SC-430: https://www.ams.usda.gov/resources/sc430

Audit Participation Agreement

You (or your food safety officer) must sign a participation agreement (Form SC-651) and provide the form to the auditor prior to the start of your USDA GAP&GHP audit. This contractual agreement outlines your requirements for participating in the USDA verification program. The form also clarifies the audit services you will receive.

As an auditee, your signature indicates that you agree to conform to laws, regulations and statutes that are applicable to the USDA GAP&GHP audit program and that you will submit your audit request at least two weeks prior to the end of your growing/harvesting/packing season. You also agree to maintain appropriate records of your operation and provide these to the auditor for review. Further, you must grant the auditor access to facilities at your location as necessary to appropriately perform the audit of requested audit scopes. Finally, you must agree to pay your bill in a timely fashion.

The auditor will sign the form on behalf of the USDA AMS. The performed audit will reflect an objective third-party verification that is based on internationally recognized audit principles. The auditor will provide an opening interview to discuss the audit’s agenda with you and an exit interview to share findings. During the exit interview, the auditor will provide you with hard-copy records of the audit report and deficiency notices (if any were found). The AMS agrees to respect the confidential nature of your operation when copying records as evidence of your operation’s practices. Any documents submitted to the AMS by the auditor will be considered voluntarily provided as your participation in the GAP&GHP verification program. The AMS agrees to issue you a certificate when all scopes have been successfully passed and agrees to publicly post and share your audit results only if you grant permission to do so.

The signatures on the form indicate a mutual agreement between you and the AMS. If you are eligible for USDA GAP&GHP certification, the issued certificate will cover a 12-month period that begins with your initial audit date. Your contractual agreement with the AMS will end (i.e., rescind the related benefits) if the auditor discovers that you no longer meet the requirements of the audit program. To reinstate the agreement (and AMS perks), the auditor will need to find evidence that you have effectively corrected all noted deficiencies. Form SC-651 is at

https://www.ams.usda.gov/resources/sc651.

Audit Request

To attain and maintain GAP&GHP certification, the USDA audits should be performed for your operation at a minimum of once per year. Your certification from a particular audit automatically will expire after a 12-month period. It is your responsibility to schedule audits for your operation. The USDA will not contact you to schedule annual announced audits.

Audit Request Form SC-237A

To request an audit, complete and submit the USDA Request for Audit Services Form (SC-237A). This form ensures that you receive the correct audit services for your operation and that the correct information will be recorded on your GAP&GHP certificate once you pass the audit. This form requires:

- Anticipated audit date(s)

- Farm contact information

- Farm /facility information (location, acres)

- List of commodities to be covered by the audit

- Type of audit services requested (e.g., USDA GAP audit) and which scopes you are requesting the audit to cover.

When submitting Form SC-237A, include multiple dates (up to six) that reflect harvest times right before scheduled deliveries (e.g., day before the farmers market). Also, specify the time of day you plan to harvest (e.g., before 9 a.m., after 3 p.m., etc.) to help the auditor plan to be on the site to observe you perform the activities.

To request an audit in North Dakota, contact: N.D. State Seed Department, 701-231-5400

When contacting the N.D. State Seed Department, be prepared with a list of anticipated audit dates that your operation will be available. All audit services are assigned on a first-come, first-served basis. Once you are assigned an initial audit date, the auditor will contact you to make arrangements. You will be provided with confirmation of your audit date and time, the audit agenda and an estimated cost for performing the services.

For each audit request (Form SC-237A) that you submit, you must provide a copy of your food safety manual and a list of the crops (including acreage) that you want the audit review to cover (see Table 4 for an example). Audit timing is critical for maximizing the value of your investment in certification. The key is to schedule your audits to get the most out of your 12-month GAP&GHP certification coverage for declared crops.

Example: Diversified Farm

Table 4. Example of Multiple-Crop Audit List

|

Example Crops |

Acreage |

|

Herbs |

1.00 |

|

Strawberries |

1.00 |

|

Tomatoes |

1.00 |

|

Carrots |

1.00 |

|

Summer squash |

1.00 |

|

Winter squash |

1.00 |

|

Brussels sprouts |

1.00 |

|

Pumpkins |

1.00 |

|

Total Acres |

8.00 |

On April 1, Dakota Farms submits a request for audit (Form SC-237A), a copy of its food safety manual and a declaration of eight crops. The initial audit visit is scheduled for June 30 and will cover the General Questions and Part 1 (Farm Review) for the entire farming operation. Additionally, the auditor will perform Part 2 (Field Harvesting and Field Packing Activities) for the herbs and strawberries that are scheduled for harvest. Because the operation’s production period is greater than 90 days, the auditor explains that there will be two unannounced verification visits during the remaining growing season. At later dates, the auditor returns (unannounced) to observe field harvesting and packing activities for the tomatoes, carrots, summer squash, winter squash, Brussels sprouts and pumpkins.

Let’s consider several audit-scheduling options to maximize the coverage.

If you want to certify a single crop with a short production season (e.g., strawberries), you could complete a scheduled audit at the beginning of the production cycle and sell GAP-certified products throughout the season. If you are a diversified farmer, you could schedule separate GAP&GHP audits for each commodity grown on your farm or schedule a single audit to cover a group of commodities.

However, three conditions apply if you choose to include multiple commodities in a single GAP&GHP audit review.

First, your multicommodity audit request must declare all commodities (e.g., strawberries, onions) that you would like to have covered in the audit review, and your manual must address the various food safety risks associated with the crops being audited. You cannot expand a requested audit at a later time to cover additional commodities. For example, if you are a berry grower and hand pick strawberries but mechanically harvest blueberries, your food safety plan must address potential food safety risks and corrective actions associated with both types of harvesting processes.

Second, the auditor must have the opportunity to observe all of the declared crops as you grow and harvest them. This requirement pertains to the initial announced audit review and any subsequent unannounced verification visits (see p. 27) that take place at your location. For example, if you schedule your audit for Aug. 1, any crops that will have been completely harvested before Aug. 1 cannot be listed on your audit request form. While the auditor may not actually observe the harvest of every declared commodity, the auditor needs to be able to observe the types of harvesting activities for certification purposes.

Third, your operation is required to participate in the appropriate number of unannounced verification visits, as determined by the length of your growing season and the declared commodities under review.

Tip for Submitting Form SC-237A:

- Send your Request for Audit form at least two to three weeks in advance of your desired inspection date.

- Include a copy of your food safety manual.

- If you plan to certify multiple crops on a single audit, schedule your initial review to take place: (a) between two production seasons, (b) when the auditor will observe the greatest variety of crops being harvested, or (c) when the auditor will be able to observe your harvesting and/or packing processes.

Audit Cycle

The GAP&GHP audit cycle comprises key phases that will require the auditor’s time, including offsite preparation (planning the audit) and onsite audit activities: opening meeting, actual audit, scope assessment and exit meeting.

Auditor’s Offsite Preparation

The offsite preliminary desk review helps the auditor gather basic information that is necessary to complete your onsite audit. The auditor will prepare for the upcoming visit by reviewing the GAP&GHP specifications, looking through your written food safety manual and identifying specific areas at your location that need to be audited. The auditor needs to form a thorough understanding of your operation to plan the direction of your upcoming audit. The planning criteria is driven by the extent that you have written and implemented a food safety program. The auditor will use the desk review to become more familiar with your operation’s food safety plan. The auditor also will take into consideration any current problems or corrective actions that may be on file and pertain to your operation.

The USDA GAP&GHP audit checklist serves as a systematic path that the auditor will follow when evaluating your operation. The auditor will use this checklist to form opinions and judgments of your operation’s conformity to GAP&GHP procedures, specifications and regulations. The preparation phase can take up to several hours of the auditor’s time, depending on the complexity of your scheduled audit, the organization and completeness of your food safety manual, and the size of your farming operation.

As you participate in yearly GAP&GHP audits, you will build an audit history. When planning for upcoming visits, auditors likely will consider any information recorded from previous announced and unannounced visits to your farm. You can expect problem areas that surfaced during previous audits at your location will be evaluated during upcoming visits to ensure that corrective actions previously taken remain effective in preventing reoccurrence.

As auditors become familiar with your operation, they will need less time to prepare for ongoing visits to your location. Your audit history is formed and the audit cycle continues with each new audit. Your audit history helps expedite an auditor’s planning process.

Onsite Audit

For your audit to be successful, the auditor must visit and observe your farm/facility while it is in operation. As seen in Table 5, the auditor will follow a step-by-step process each time he or she visits your location. Generally, you should plan for an onsite audit to last two to five hours. Of course, the length of time will depend upon the size, scope and type of audit being performed, as well as the complexity of your operation. For example, an audit for a small owner-operated farm would take considerably less time compared to an audit for a larger diversified farm.

Table 5. Typical Audit Day Process

|

Audit Day |

|

|

1. Opening Meeting |

|

|

2. Audit is Conducted |

|

|

3. Auditor Assesses the Scopes |

|

|

4. Exit Meeting |

Opening Meeting

Upon arrival, the auditor will make his or her presence known and immediately meet with your food safety officer and you. During this opening meeting, the auditor will clarify the purpose of the visit and verify that you have signed a contract to cover the intended audit services. If you have not yet signed the Participation Agreement Form (SC-651), the auditor will collect your signature during the opening meeting. Once your signature is in place, the auditor will explain the audit agenda, confirm the audit scope(s) that you have requested and communicate how the audit will proceed. The auditor will refer to the GAP&GHP checklist and ask for pertinent records and documentation that need to be reviewed. During the opening meeting, you and your food safety officer will be able to ask questions about the audit process. The opening meeting serves to clarify what the audit process entails so you and your food safety officer know what to expect throughout the day. The duration of the opening meeting is largely dependent on the complexity of your audit scopes and your familiarity with the GAP&GHP audit verification program.

Conducting the Audit

The auditor will follow the GAP&GHP audit checklist and keep notes while reviewing your documents and records, interviewing employees, examining products, and observing the processes and procedures of your operation. The checklist and notes will help the auditor form a determination of how well your operation complies with the written food safety plan and the USDA GAP&GHP program requirements.

In some instances, an auditor may need to review additional records to verify your conformity to a particular question, even though the checklist item does not indicate that documentation is required. As noted earlier (see p. 16 of this manual), the majority of the checklist questions are designated with the letter “P,” “R” or “D” to remind the auditor when to review policies, records or a combination of both. The coded reminders assist the auditor in verifying the extent that your documentation accurately represents your operation’s food safety program and that your policies, procedures and food safety manual conform to the USDA GAP&GHP requirements and local, state and federal regulations.

Process verification is an important component of conducting an audit. The auditor will ask questions of your employees and contracted staff during the observation process. The practices and actions of your employees and contracted staff will be observed for compliance with standard operating procedures and food safety requirements. The auditor’s observations build upon the items listed on the GAP&GHP checklist. You can expect the auditor to focus on areas of importance such as the worksite, rules that employees must follow, safety regulations, etc. As discoveries are made, the auditor will document observations and findings. When nonconformity is observed, the auditor will ask the person(s) responsible in the area of concern to review and confirm the finding. If your policy is to require special training, education, experience or certification for certain employees or contracted staff, the auditor will examine and verify the status of requirements met by all applicable individuals.

Assessing the Scopes

Once observations around your operation are complete, the auditor will need a private area to review his or her notes and findings, tally the audit scores for each scope reviewed, determine the severity of nonconformities (if any exist), make necessary telephone calls to USDA supervisors, identify relevant documentation, write the audit report and make copies of the report, including all supporting documentation.

The product of the auditor’s review is a written report of your operation. A number of important items constitute the audit report: the completed checklist, a scoresheet and the corrective action report (CAR). The auditor will initiate a CAR if he or she has observed any nonconformities or “automatic unsatisfactory conditions” during the review of your operation.

When an error is discovered and the documentation contradicts the checklist question requirement(s), the auditor will score that question as lacking conformity to your food safety program. The auditor will photocopy any documents or records that are discovered to be inaccurate and/or reflect deviations from your operation’s SOPs. The photocopies of such documents will become official records of your audit report. However, when such documents contain your personally identifiable information, the auditor will include written descriptions of the operational deviations in the audit report instead of photocopies of the documentation. Overall, the CAR will include the auditor’s written descriptions of any observed practice(s) or procedure(s) that led to your audit failure. Such detail will include the time, location and specific checklist question(s) or item(s) that the auditor observed and noted as lacking conformity to food safety standards recognized by the USDA and industry.

Exit Meeting

Generally, the last phase of the audit day is the exit meeting that takes place between the auditor, your food safety officer and you. During this meeting, the auditor will review the findings and discuss observations. The duration of the exit meeting will depend on the size of your operation, the audit scope(s) covered and amount of detail in the audit report. Within your audit report, you will find written explanations for all checklist questions that the auditor marked with “No” or “N/A.” Keep in mind that the primary purpose of conducting the audit is to: (a) verify your operation’s compliance with the USDA GAP and GHP audit checklist items, (b) verify the implementation of your written food safety plan and (c) highlight any corrective actions that you will need to take in response to nonconformities discovered during the audit.

You will be provided a completed copy of the audit report plus any supporting documents and supplemental records that have been attached to the report. At this time, you will be have opportunity to ask questions about any aspect of the audit and address the checklist items that the auditor marked “No” or “N/A,” including the corresponding explanations for such responses. Information that is discussed during the exit meeting may have a bearing on the nonconformity report that the auditor has prepared. Before leaving, the auditor will inform you of the number of required follow-up and unannounced surveillance visits that you can expect.

Nonconformities/Corrective Actions

The auditor is obligated to file a corrective action report (CAR) for any GAP&GHP audit that fails due to nonconformities from a specific “automatic unsatisfactory” condition or when a particular audit scope fails to meet the required minimum program requirements (e.g., a passing score). The auditor must submit the CAR prior to conducting a follow-up audit at your location. A follow-up audit can never be performed on the same day as your initial audit visit because the auditor must allow adequate time for you to fully implement long-term corrective actions and address problems identified in the CAR.

If you wish to continue in the GAP&GHP verification program, you must develop a plan to resolve all nonconformities listed on the CAR. You will typically complete two steps to address the CAR requirements: (a) short-term corrective action(s) and (b) long-term corrective action(s) often called root-cause analysis. Short-term corrective actions are steps that you will take immediately to address deficiencies noted in the CAR. Long-term corrective actions require more time because you need to find the root cause of the deficiency and determine if the problem occurs frequently or requires a long-term investment in resources to prevent recurrence. Typically, the implementation of long-term corrective actions will require changes in your standard operating procedures or policies that comprise your food safety program.

You are required to write a corrective action response plan that includes a list of short-term and long-term actions to be taken to effectively address the problem(s). You must submit your written response plan to the auditor for review and approval. The auditor will determine the efficacy of your short-term solution(s) and expect your root-cause analysis to include steps that will prevent recurrence. The auditor will look for your short-term corrective action plan to review (a) details of the operational failure(s), (b) immediate solutions to address the problem(s), (c) identification of an individual responsible for verifying that corrective actions are taken, and (d) the extent that all corrective action(s) conform to the policies and SOPs of your food safety program. (See below for a hypothetical example.)

Hypothetical Example of Nonconformities and Corrective Actions

Scenario

The auditor checked all four of your farm’s restroom facilities throughout the audit day and consistently found used paper towels spilling out of the trash receptacles and piles of used paper towels and other trash items scattered across the floors. The auditor confirmed that this unsanitary situation extended beyond a single restroom facility and that the problem persisted throughout the day of the audit. In turn, the auditor reviewed documents in your food safety manual and discovered that your food safety program did not designate a specific individual to monitor and supervise the cleanliness of your restroom facilities. As a result, the auditor completed a corrective action report (CAR) and failed your audit due to “automatic unsatisfactory conditions in all restrooms due to overflowing trash receptacles and trash on the floors.” In turn, you prepare your response plan.

Your Proposed Corrective Action Response Plan: I acknowledge that our employees are following appropriate handwashing procedures, as evidenced by the overflowing trash bins and paper scattered across bathroom floors. However, all restroom facilities must be maintained in a sanitary condition as a requirement for preventing the spread of bacteria. During our audit, it was discovered that all of our restroom facilities presented unsanitary conditions due to “overflowing trash receptacles and trash on the floors.” This unsanitary condition stemmed from a lack of established restroom maintenance procedures for our operation and resulted in the automatic failure of our audit on July 1, 2018.

To address the automatic unsatisfactory condition related to our restroom facilities, I propose the following short-term corrective actions: On July 1, 2018, I will assign eight individuals to immediately empty all trash bins, clean the floors and sanitize all of the restrooms. Further, I will designate our food safety officer (Jane Doe) to make sure the assigned staff have carried out all steps necessary to correct the immediate problem and that the task completion is recorded in our food safety manual. Ms. Doe will supervise ongoing efforts to maintain the cleanliness of the restrooms until we have a permanent restroom facilities manager in place. Because the nonconformity posed an immediate food safety threat to our operation, the short-term action steps proposed in this corrective action response plan were performed on the day of our initial audit, July 1, 2018.

To address the automatic unsatisfactory condition related to our restroom facilities, I propose the following long-term corrective actions: On July 2, 2018, I will create a permanent staff position to manage the cleanliness of all restroom facilities. I expect that the restroom facilities manager will be placed in position and fully trained to perform duties by July 9, 2018. Between July 2, 2018, and July 8, 2019, Ms. Doe will develop the necessary SOPs, policies, training procedures and maintenance tracking logs to ensure that all restrooms are cleaned regularly throughout each day and that the facilities remain adequately stocked with soap, toilet paper and paper towels at all times. Our restroom facilities manager will report directly to our food safety officer, Jane Doe.

If the auditor believes your corrective actions will reasonably address the nonconformities that resulted in audit failure, he or she likely will sign and finalize the CAR to indicate acceptance of your proposed actions and timetable for implementation. If proposed actions and the timetable do not constitute short- and long-term solutions to the problem, the auditor will request that you review, revise and resubmit a corrective action response plan for approval. Any corrective actions that are accepted will not be approved officially until the auditor returns for a follow-up onsite visit and has the opportunity to verify that your implemented actions provide evidence of long-term effectiveness.

On the follow-up visit, the auditor will check to see if changes stemming from the corrective actions have been written into your food safety plan. The CAR will become a permanent record of your audit history, and the problem areas likely will be revisited each time an auditor makes a visit to your operation, including audits that you schedule in the future.

Follow-up Audit

You can expect a follow-up audit if your operation’s initial audit or unannounced surveillance review(s) failed to meet GAP&GHP program requirements. You will need to address all nonconformities noted in your corrective action report (CAR) before scheduling a follow-up audit. The follow-up review follows the same process as the initial audit. Upon arrival, the auditor will make his or her presence known and immediately meet with your food safety officer and you. During this opening meeting, the auditor will clarify the purpose of visit and explain the scope(s) to be reviewed. The auditor will follow the GAP&GHP audit checklist and keep notes while reviewing your documents and records, interviewing employees, examining products and observing the procedures of your operation.

If your operation failed the initial audit review due to an “automatic unsatisfactory condition,” your follow-up audit will include a review of all scopes listed in the initial audit request. (See Scenario 1 below for a hypothetical example) If your operation failed to meet GAP&GHP program requirements because of low scores for some (but not all) of your reviewed audit scopes, your follow-up audit only will include a review of the scopes with the low scores. (See Scenario 2 below for a hypothetical example) Once the observation of your operation is complete, the auditor will work privately to review audit notes and findings, and tally your scores for the repeated and completed scope(s). The auditor will complete a corrective action report (CAR) if any nonconformities exist. You will have the opportunity to discuss the auditor’s findings and ask questions during the closing meeting. The auditor will provide a copy of the of the audit report during the closing meeting.

Follow-up Audit Scenario 1: Your initial audit consists of three GAP&GHP scopes: General Questions, Part 1 and Part 2. The auditor discovers that your field sanitation units are located in close proximity and uphill of your strawberry field, creating a possibility of spilled sewage running downhill into the crop production area. You passed the audit scopes for General Questions and Farm Review (Part 1) but failed the entire audit because of the automatic unsatisfactory condition for Part 2 (Field Harvest and Field Packing Activities, Questions 2-4). During your follow-up visit, your audit will consist of all three scopes: General Questions, Part 1 and Part 2.

Follow-up Audit Scenario 2: Your initial audit consists of three GAP&GHP scopes: General Questions, Part 1 and Part 2. To pass each scope, you need to score 80 percent of your total adjusted points. (See the audit scoring section on p. 29.) You scored 94 percent (160 out of 170 total adjusted points) for the General Questions scope; 78 percent (140 out of 180 total adjusted points) for the Farm Review (Part 1) scope and 92 percent (165 out of 180 total adjusted points) for the Field Harvest and Field Packing Activities (Part 2) scope. You have successfully passed the General Questions and Part 2 scopes. During your follow-up visit, your audit will consist of the Farm Review (Part 1).

Unannounced Verification Visits

Unannounced visits are an important component of the USDA GAP&GHP audit verification program. These visits coincide with an initial or follow-up audit that has been performed and successfully passed within a given season. The purpose of an unannounced review is for the auditor to verify consistency in your operation’s conformance with requirements of the USDA GAP&GHP program and with those of your food safety plan. As the name implies, you will not know specifically the date that the auditor will show up to perform surveillance. The number of minimum required unannounced verification visits to your location during a season is dependent on the audit scope(s) performed, the number of commodities grown in a production area during a given season and the number of days your operation has been in business.

Conditions for Part 1 Audit

Following a GAP&GHP audit for Part 1, you are not required to have unannounced verification visits if you grow only one commodity in a production area during the season (e.g., only potatoes or only onions, etc.). However, unannounced verification visits are applicable to your operation if you grow multiple commodities in the same crop production area in the same growing season. (See Table 6.)

|

Table 6. Number of Commodities Grown |

|

|

Number of Commodities |

Number of Required Visits |

|

1 |

0 |

|

> 1 |

1+ |

|

Note: Minimum* Number of Required Unannounced Visits, Based on Number of Commodities Grown in Same Crop Production Area During Season, Following a GAP&GHP Audit (Part 1). |

|

Conditions for Parts 2 through 6 Audits

Following GAP&GHPaudits for Parts 2 through 6, you are not required to have unannounced verification visits during the season if you have been in operation less than 31 days. However, if you have been in operation from 31 to 90 days, you can anticipate a minimum of one unannounced verification visit from the auditor during the season. If you have been in operation more than 90 days, you can expect to have at least two unannounced verification visits during the season. (See Table 7.)

|

Table 7. Days in Operation |

|

|

In Operation |

Number of Required Visits |

|

< 31 days |

0 |

|

31- 90 days |

1+ |

|

> 90 days |

2+ |

|

Note: Minimum* Number of Required Unannounced Visits, Based on Number of Days in Operation During Season, Following a GAP&GHP Audit (Parts 2, 3, 4, 6). |

|

*Note: In any situation, the USDA reserves the right for the auditor to conduct additional unannounced verification visits if there is suspicion that your operation is noncompliant with the requirements of the GAP&GHP program and/or your written food safety program.

Automatic Unsatisfactory Conditions

Any variety of situations may arise that will require the auditor to terminate an audit upon the discovery of unsatisfactory conditions. Although not meant as an exhaustive list, the USDA considers the following conditions as automatic grounds for audit failure:

- The farm does not have a written food safety plan in place or no one is designated to oversee the food safety program.

Your operation must have a documented food safety program in place. If you are missing this document, the auditor cannot verify that the implementation of your food safety program conforms to USDA GAP&GHP standards. Without a written plan, the auditor is obligated to terminate your audit. - No one is designated to oversee and implement the food safety plan.

You must designate an individual to oversee your food safety program, and this individual must be named in your food safety manual. The lack of a designated food safety officer demonstrates a lack of commitment to food safety. This unsatisfactory condition will be grounds for the auditor to fail your audit. - An immediate food safety risk is present when produce is grown, processed, packed or held under conditions that promote or cause the produce to become contaminated.

Your auditor will look for immediate food safety risks while reviewing your operation’s processes. If the auditor believes your processes have created product contamination or conditions that are likely to cause product contamination, your operation will not meet the minimum GAP&GHP program requirements, and the audit will be terminated. Examples of this would be the use of nonpotable water in the product washing process, a leaky sewer pipe in the production area or livestock found in the irrigation water. - There is presence or evidence of rodents, or an excessive amount of insects or other pests in the production area during packing, processing or storage.

The auditor immediately will stop the audit if the production or storage areas show evidence or infestations of rodents, birds or other mammal-type pests or show evidence of feces from various pests. An example of this condition would be the harvest of strawberries from a production area infested with rabbit droppings. - Observation of employee practices (personal or hygienic) that have jeopardized or may jeopardize the safety of produce.

Your employees must understand the threats to product safety when proper hygienic practices are not practiced on a constant basis. The following examples would cause the auditor to terminate your audit: An employee puts partially eaten product back into the product flow zone, spits on product or into product flow zones, disposes used toilet paper on the restroom floor or uses the toilet facility but does not wash hands before returning to work. - Falsification of records.

The USDA considers falsification of records an egregious offense that will result in an automatic failure of your audit. An example of this would be changing water test results or changing the dates of the actual test.

Audit Scoring

The auditor will refer to the checklist that corresponds to your audit scopes to evaluate your operation’s conformity to the GAP&GHP audit requirements and those of your food safety program. While a perfect audit score is obtainable, some minimal exposure to risk is assumed when you choose not to implement certain measures pertaining to the audit checklist items. However, the USDA audit standards are not meant to eliminate all risks. Rather, audit participation serves to validate your food safety plan as a way to reduce risk on your farm while achieving certification.

The goal of your audit is to demonstrate to the auditor that your operation has successfully implemented a food safety program that meets GAP&GHP audit requirements so that you may receive certification. You and your food safety officer should understand how the GAP&GHP audit checklist items are organized, how questions are structured and how the auditor will categorize the responses for tallying your audit scores.

Because the USDA GAP&GHP checklist is generic and can be used for any commodity and operation, there may be instances when a particular question does not pertain to your operation. In such a situation, the auditor will categorize the item as not applicable (N/A), provide a brief explanation in the comments section justifying the N/A designation and exclude the item from your audit score calculation. Additionally, the checklist contains some questions where designating N/A is not an option, and the auditor must designate either a “Yes” or “No” response. When any form of nonconformance is identified for any of the items, the auditor will include an explanation in your audit report to clarify the determination.

The auditor follows a sequential process to score the items. First, the auditor will ask to see specific policies (P) and/or records (R) when required by checklist items. Second, the auditor will rate the materials for the relevant checklist items using three categorical options: Yes (the policies and records conform to GAP&GHP standards), No (the materials do not conform to GAP&GHP standards) or N/A (the item cannot be answered).

Third, the auditor will convert some of the categorical ratings to a point value. The scored items will range in value from five to 15 points. You will receive all available points for each checklist item that the auditor marked “Yes” and zero points for each item marked “No” or “N/A.” With the exception of a food defense (Part 7) audit, there are never partial points awarded for partially completed or minimally acceptable procedures pertaining to any checklist items. Fourth, the auditor will tally your points within each scope reviewed. A passing score within a scope is defined as 80 percent of the possible points (or adjusted points if necessary) for a scope, with no automatic unsatisfactory conditions discovered.

Fifth, the auditor will identify whether or not you have passed all scopes reviewed, which is a necessary requirement for passing the entire audit. For example, if your entire audit comprised General Questions and Part 1, you will need to earn 80 percent of your adjusted total points for the General Questions and 80 percent of your adjusted total points for Part 1 to pass the entire audit. (See the hypothetical examples, Tables 8-13 for an understanding of how adjusted and lost points impact the outcome of audit scopes.)

Table 8. Hypothetical GAP Audit - Adjusted Points in the General Questions Scope.

|

Item |

Auditor Observations and Comments |

Points |

Code |

Type |

|

Implementation of a Food Safety Program |

||||

|

P-1 |

Has implemented GAPs that are documented in the food safety manual |

Yes |

D |

|

|

P-2 |

Jane Smith is named in the food safety manual as the designated food safety officer. She has completed trainings and is qualified for the job. |

Yes |

D |

|

|

Traceability |

||||

|

G-1 |

Has a documented traceability program in place. Records are maintained to accurately trace products. |

15 |

Yes |

D |

|

G-2 |

Has not yet completed a mock recall, but this is the farm’s first time applying for certification and a mock recall is not yet required. |

10 |

N/A |

R |

|

Worker Health and Hygiene |

||||

|

G-3 |

Maintains records for all drinking water and handwashing water test results. |

10 |

Yes |

R |

|

G-4 |

Has a policy on worker/visitor health and hygiene training. |

10 |

Yes |

P |

|

G-5 |

Training log shows that all staff have been trained on proper sanitation and hygiene practices. |

15 |

Yes |

D |

|

G-6 |

Employees and visitors are following good hygiene/sanitation practices |

15 |

Yes |

|

|

G-7 |

Employees who handle or package produce are washing their hands before beginning or returning to work. |

15 |

Yes |

|

|

G-8 |

Signs are posted to enforce handwashing practices for all staff before beginning or returning to work. |

10 |

Yes |

|

|

G-9 |

The house restroom is clean; portable restrooms in field sanitation facilities are clean and properly supplied with supplies and potable water. |

15 |

Yes |

|

|

G-10 |

Cleaning and service logs show that portable restrooms are adequately cleaned and serviced. |

10 |

Yes |

R |

|

G-11 |

Has a policy on smoking and eating areas. |

10 |

Yes |

P |

|

G-12 |

Has a policy for addressing workers with foodborne illness. |

15 |

Yes |

P |

|

G-13 |

Has a policy on how to deal with product/food surfaces that come in contact with blood. |

15 |

Yes |

P |

|

G-14 |

Has a policy on what workers do when they get hurt. |

5 |

Yes |

P |

|

G-15 |

Keeps copies of licenses for all personnel who apply regulated preharvest and/or postharvest materials. Logs are kept for all personnel trained on proper use of applying nonregulated materials. |

10 |

Yes |

R |

Codes: P (SOP); R (records); D (records + SOP); Yes (compliant); No (not compliant); N/A (not applicable).

Table 9. Pass/Fail Calculations for the Hypothetical GAP Audit - General Questions Scope

|

Calculations |

Total Points |

||

|

Total Points Available |

180 |

180 |

|

|

Subtract Points for N/A Questions* |

G-2 (-10 points) |

- 10 |

-10 |

|

Adjusted Total Points |

180 – 10 = |

170 |

|

|

Required Passing Score (80%) |

170 x 0.80 = |

136 |

|

|

Farm’s Calculated Points |

Based on “Yes” responses |

160 |

160 |

|