Site-specific Farming: Active Optical Sensor Algorithms for Corn Yield Prediction and a Corn Side-dress Nitrogen Rate Aid (SF1176-5, Reviewed May 2019)

Availability: Web only

Active optical sensor algorithms: how they work and how they can be used to calculate N requirements in the field.

Active optical light sensors have been available for agricultural use for about 20 years. People are most familiar with passive light sensors.

A passive light sensor can detect visible light and other electro-magnetic radiation originally emitted by the sun or another light source. The instrument senses the reflection of the light. Examples of passive light sensors are aerial photography and satellite imagery.

An active optical light sensor emits its own light, usually in tightly specific wavelengths, and has the ability to measure the intensity of the light reflected into the instrument, compared with the light emitted.

The active optical sensors that relate to this publication have the ability, through the modulated light pulses emitted (sort of like a light-based UPC code-length of on-off patterns), to filter out light that does not conform to the same modulation. Therefore, the readings the instrument records are not influenced by changes in sunlight, cloud cover or clouds passing over during sensing, and can provide similar readings at night or during the day. The only condition that hinders measurement consistency is leaf wetness from rain, recent irrigation or early morning dew.

The two active optical sensors recently tested in corn nitrogen (N)-rate trials are the GreenSeeker (Trimble, Sunnyvale, Calif.) and the Holland Scientific Crop Circle (Holland Scientific, Lincoln, Neb.). During 2011 and 2012, the GreenSeeker used only a red and near infrared light source/sensor. In 2013, the new-style GreenSeeker also included a red-edge light source/sensor.

From 2011 through 2013, the Crop Circle sensor included red, red-edge and near infrared light sources and sensors. The red, near infrared and red-edge light sources differed in wavelength, so the algorithms for one cannot be used as a predictive tool by the other.

Algorithms

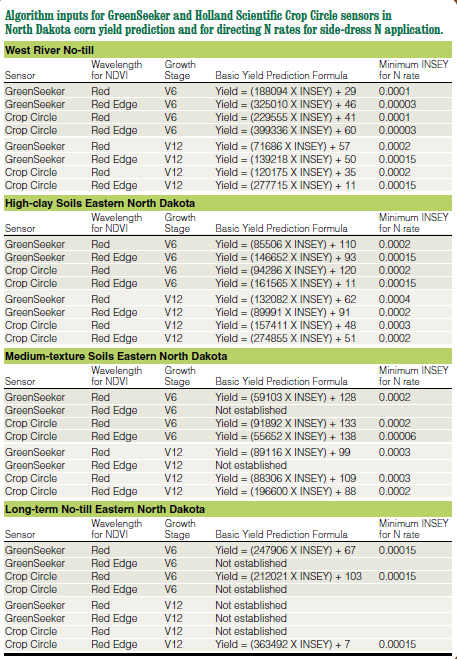

Some algorithms were developed for the GreenSeeker red-edge option, but some soil/tillage categories had insufficient sites to confidently publish a red-edge algorithm, so none are available. Growers might develop some themselves using a suggested technique related in this publication or opt to use a sensor that already has an algorithm as a starting point.

The algorithms published here were developed during several years using N-rate corn trials from across North Dakota only. Some algorithms may predict yield, but the yield might have been influenced by factors other than N. These algorithms consider that the only reason for differences is probably N.

The choice of algorithm will depend on the region of the state, the tillage practice and soil texture category. North Dakota is divided into West River (everything west of the Missouri River) and Eastern North Dakota (everything east of the Missouri River). Long-term no-till is defined in eastern North Dakota as a field in continuous no-till or shallow one-pass seeding for at least six years.

Tillage deeper than 2 inches is considered conventional till. No-till after conventional till is considered conventional till until the field is continuous no-till for at least six years. An anhydrous ammonia or strip-till knife trip is not a conventional tillage pass.

A high-clay soil is more than about 30 percent clay and includes soils with a Bearden texture or higher clay. Fargo, Hegne, Viking, Bearden and related soils fall into this category. A medium-textured soil includes silt loams, fine sandy loams, loams, sandy loams and loamy sands.

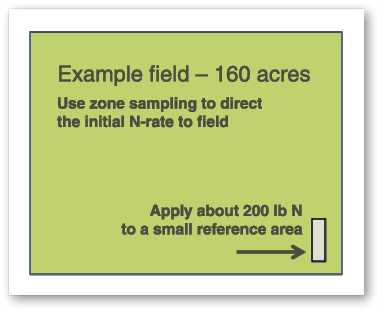

How to Use an Active Optical Sensor

To use an active optical sensor for the purposes of site-specific N side-dress N application, an N nonlimiting area in the field must be established. If the soil test N within the field is less than about 80 pounds per acre on a 2-foot soil test, a variable-rate base N rate should be applied so that the preplant N total is at least 100 pounds per acre. This is important because applying supplemental N to stressed corn early in the season is not nearly as productive as supplementing healthy corn. The use of zone soil testing to prepare for this base rate is strongly recommended unless a recent history of manure application makes grid sampling more practical.

At the time of the base N application preplant, a small area the width of the applicator and about 100 feet long within soil category within intended hybrid should receive an N rate to achieve at least 200 pounds of N per acre total for the field area. This is the N nonlimiting area.

The rainfall patterns should be considered between preplant N application and side-dress application. If a single rainfall event drops more than 2 inches of rain on a sandier soil, some leaching of the preplant application may have occurred. Similarly, if rainfall is more or less continuous on high-clay soils between preplant and sidedress, significant denitrification and gas loss of N may have occurred. In either case, supplementing the N nonlimiting area may be required so that the nonlimiting standard is a more true representation of a real N nonlimiting area.

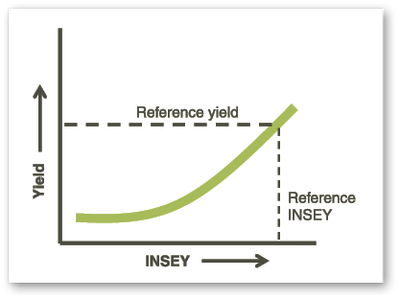

At the time of side-dress, the growing degree days from the planting date should be entered into the controlling computer unit. This is necessary to normalize the data through the calculation of INSEY (in-season estimate of yield). The INSEY is a normalizing number that allows the application to be made on plus or minus a couple of corn leaf stages while using the same algorithm. Separate algorithms are available for a V6 and V12 growth stage.

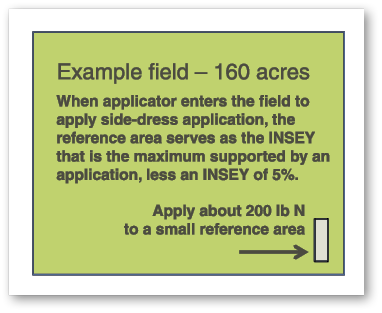

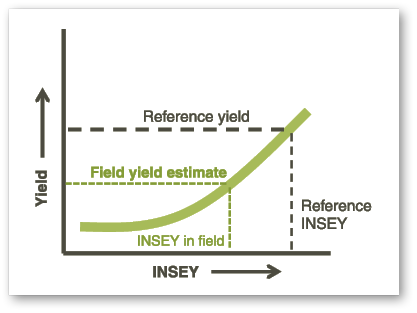

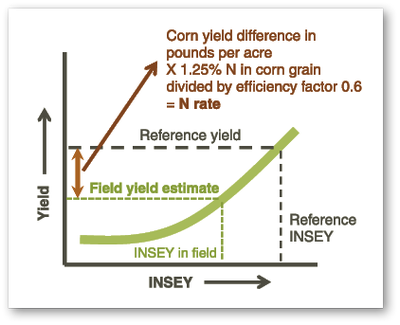

When the applicator enters the field with the sensor or sensor array attached in front of the applicator unit, the instrument first senses the N nonlimiting area. The average reading from the area is entered into the spray controller. If the readings in the rest of the field are within 5 percent of the N nonlimiting area, then no rate of N would be expected to increase yield more than the yield in the N nonlimiting area. If the reading is more than 5 percent less than the N nonlimiting area standard, the algorithm predicts the lower yield probable if no N is applied. The difference between yield predicted in the N nonlimiting area and the yield predicted outside the N nonlimiting area is used to calculate the N rate:

Yield difference (bushels per acre)

X 56 pounds per bushel

X 1.25 percent N in the grain

= (N required to make up yield difference) divided by an efficiency factor

= (N rate, pounds N per acre)

The efficiency factor usually used for an in-soil application, such as anhydrous ammonia or coulter-applied UAN, is 0.6.

In a stream-bar UAN application or surface urea + NBPT application, followed by rainfall of at least ½ inch within a week or so, 0.6 also might be used. If a surface application might be followed by a considerable stretch of dry weather, a value of 0.2 might be the highest factor one may expect.

An additional algorithm consideration is areas in the field that have low stand, bare areas, or areas with poor growth due to high salts or other nutrient problems. Each algorithm table has a column suggesting the minimum INSEY for the N rate within a sensor and growth stage. The controller should be programmed so that if the INSEY is below the suggested minimum value, no N is applied.

Other Considerations

In our work, we had several sites where the INSEY was lower in the N nonlimiting area than the rest of the plot. If this happens in the field, the reason usually is that the field or area of the field with the N nonlimiting area is sulfur (S)-deficient. Application of a soluble sulfate or thiosulfate fertilizer should be applied as soon as this condition is evident. Once the S is taken up by the corn, the usual higher or similar greenness of the N nonlimiting area should be realized.

If weeds cover the soil surface, the sensor will register not only the crop reflectance, but the weeds as well. The population of weeds within the field should be low for the algorithms to be effective.

Some growers might want to program a minimum rate of side-dress N into the algorithm even if the difference between the field reading and the N nonlimiting area is less than 5 percent. A value of between 30 and 50 pounds N per acre would be a reasonable value for a minimum N rate.

The minimum INSEY for N rate is required because INSEY values below this at the growth stage indicated only appear if the stand is poor or the corn is suffering from another non-N related issue.

Example of Algorithm Calculation

Yield predicted in N nonlimiting strip:

120 bushels per acre

In-field yield estimated: 60 bushels per acre

Difference between N nonlimiting yield prediction and in-field yield prediction:

60 bushels per acre X 56 pounds per acre

= 3,360 pounds corn per acre difference if no N is applied.

3,360 pounds corn per acre

X 0.0125 pounds N per pound of corn

= 42 pounds N per acre

42 pounds of N deficiency divided by

0.6 efficiency factor

= 70 pounds of N per acre required at that location.

Example: how sensor algorithm works and calculates the N requirement in the field.

Acknowledgments

The North Dakota Corn Council, International Plant Nutrition Institute, Pioneer Hi-Bred International and the U.S. National Science Foundation granting agency provided funding to support the data required to produce these algorithms.