Planning To Irrigate: A Checklist (AE92, Revised Dec. 2018)

Availability: Web only

On most farms, the number of irrigated acres is usually much less than the dryland acreage. Therefore, irrigation must be integrated into the total farm enterprise.

Irrigation requires intensive fertility management, improved weed and insect control, timely identification of disease problems and, above all, accurate recordkeeping. Allocating the time for managing the irrigation system is a key factor in the success of any irrigation project. The need for information and assistance from public and private sources becomes more critical under irrigation.

When considering an investment in irrigation, one of the first questions to ask is” "Why do I want to irrigate?" The primary reason should be to increase net farm income over dryland production.

Increased income may result from the ability to grow longer-season crops or a high-value specialty crop, provide an assured forage supply for animal operations or improve crop rotations. Irrigating as insurance against insufficient rainfall just because the water is available or because you have fields with irrigable soils are poor reasons. The higher yields possible with irrigation require greater management skills and inputs in the form of fertilizer, seed and possibly pest control.

When you have decided that irrigation will fit into your farming enterprise, use the checklist to guide the irrigation development process.

STEPS TO FOLLOW

1. Determine if your soils are irrigable.

2. Determine the quantity and quality of water required.

3. Determine the availability of power and the type of irrigation equipment you’ll need.

4. Determine whether irrigation will be cost-effective in your farm enterprise.

5. Determine whether you can obtain financing.

6. Select and manage your irrigated crops.

✓ Step 1: Determine if Your Soils are Irrigable

Not all soils can be irrigated due to various physical problems such as too much slope, low infiltration rates or poor internal drainage that may cause salt buildup. Soils are classified as irrigable, conditional or nonirrigable and are defined in the following way:

Irrigable soils have no restrictions for sustained irrigation using proper application rates, amounts and water quality.

Conditional soils have restrictions for sustained successful irrigation due to such factors as water table elevation, layers of low permeability, potential for salinization and steep slopes. Some restrictions can be corrected with drainage. Conditional soils should have a detailed field level soil survey conducted, ideally by a registered soil classifier, before irrigation is developed.

Nonirrigable soils have severe restrictions to irrigation and should be developed only where they are minor inclusions into irrigable soils.

Consult the county soil survey to learn the name or number of all the soil series in the field to be irrigated, then use Extension publication AE1637 to determine the irrigability classification.

Sources for soils information:

- The Natural Resources Conservation Services (NRCS) online Websoil Survey.

- Published county soil survey books in the Extension or NRCS offices are useful but may not have the latest soils information.

- NDSU Extension publication AE1637. “Compatibility of North Dakota Soils for Irrigation,” is available from county Extension offices or online.

✓Step 2: Determine the Quantity and Quality of Water Required

The water supply is the heart of any irrigation development, and a water permit is required for all water appropriations except domestic use, livestock, and noncommercial lawn and garden irrigation of five acre or less.

The amount of water you will need is about 6 gallons per minute per irrigated acre during July and August. For example, if you want to irrigate 100 acres, you will need a water source that can produce about 600 gallons per minute.

A water permit must be obtained before constructing a well or any device for capturing water from a surface source and installing an irrigation system. The application form and instructions for an irrigation water permit can be obtained from the office of the state engineer. You may need to fill out the permit application with the help of a local surveyor or consulting engineer.

When a water permit is first issued, it is called a conditional permit. When the water source is developed and the irrigation system has been installed and inspected by the state engineer, the conditional permit is changed to a perfected permit.

If surface water (pond, lake, river, etc.), is the source, whether sufficient water will be available during the summer months must be determined. If ground water is the source, online and published aquifer information can be obtained from the North Dakota State Water Commission (see sources of information at end of this section). The data can be used to determine the location, size and potential production capacity of the aquifers at the field to be irrigated.

Small aquifers that are not shown in the county ground water survey may exist. Drilling test holes is the only sure way to determine if sufficient water is available from the aquifers in these areas.

A permit is not required to drill test holes. However, before drilling test holes, consulting a ground water hydrologist with the Appropriations Division of the North Dakota State Water Commission would be wise.

If sufficient water is available, one or two of the test holes should be developed as observation wells to monitor the effect of irrigation pumping on the aquifer water level and assist in the diagnosis of production well problems should they occur in the future.

Ground water and surface water chemistry should be determined to make sure the water is suitable to apply to the soil in the field of interest. A water sample can be sent to the NDSU Soil and Water Testing Laboratory for analysis. The location of the field should be included with the water sample to obtain a soil-water compatibility recommendation. Soil-water compatibility is very important because the soil type will determine the quality of water that can be used.

Sources of information for water:

County Extension or Natural Resources Conservation Service (NRCS) offices

Appropriations Division of the North Dakota State Water Commission: for general information on the water permitting process, phone (701) 328- 2754; for online GIS-based water resource information.

NDSU Soil and Water Testing Laboratory

Irrigation water analysis form (AE1360)

✓Step 3: Determine the Availability of Power and the Type of Irrigation Equipment You’ll Need

Power Source

If available, electricity is generally the preferred source of power. However, if existing power lines are more than a mile from the pump site, using an internal combustion engine may be more economical. Electricity has some advantages over engines, such as lower pumping costs, less maintenance, reliability and ease of operation.

Construction costs and repayment for the extension of power lines vary with each electrical provider. An estimation of annual power use, costs and construction repayment is necessary to determine the most economical power source.

For electric pumps, three-phase power is preferred but often is not available or too expensive to bring to the pump site. Variable-frequency drives (VFDs) and rotary or static phase converters will transform single-phase power to three-phase power. Early contact with the power supplier is necessary to allow time to plan and construct facilities.

Equipment

Select an irrigation system (pump, motor, pipeline, water application equipment) that fits your needs relative to water supply, irrigated acreage, crop rotations, labor requirements and the power supply. Irrigation system pressure requirements and sprinkler selection should be based on soil and topography. Remember, this equipment will have a useful life of 30 to 35 years or more.

Visit irrigators with similar systems; listen to their experiences and opinions to determine the advantages and disadvantages of their systems. Select a dealer who is well-established and capable of designing a good system, and has a good service record. Buy as much of the entire system from one dealer as possible. This may help eliminate problems of responsibility and installation, plus, when an emergency happens during the growing season (lightning strike, tornado, strong winds, etc.), timeliness of repair is crucial.

The pump and motor should be adequately sized to fit the flow capability of the well or water supply and meet the pressure requirements of the irrigation system. The pipe size and wall thickness should be selected to match the flow rate and pressure requirements.

After installation, pump and motor information, along with irrigation system specifications, should be furnished by the dealer and/or well driller and filed for future reference. Typical equipment costs are shown on the last page.

For information on irrigation equipment and power requirements:

- NDSU publication AE91, “Selecting a Sprinkler Irrigation System,” is available at county Extension offices or online .

- Contact irrigation dealers, other irrigators in the area, licensed well drillers and the local electric power supplier.

✓Step 4: Determine Whether Irrigation Will be Cost-effective in Your Farm Enterprise

Detailed crop budgets covering economic and cash costs should be prepared for the proposed irrigated cropping system. If the budgets show an adequate return to labor, capital and management, then a total enterprise analysis should be made to determine how irrigation will fit into the farming operation.

For example, irrigation of grass or hay may not bring a big return by itself, but coupled with a livestock operation, it may increase net returns and lend stability to the farm enterprise. Irrigation alone does not assure financial success. It requires planning and good management on the part of the farm operator.

For information on crop budgets:

Irrigated crop budget worksheets and Excel files can be obtained at county Extension offices or online.

✓Step 5: Determine Whether You Can Obtain Financing

Irrigation manufacturing companies represented by most irrigation dealers have financing programs for new equipment. In addition, the Bank of North Dakota has an interest buy-down program for investment in new irrigation equipment when certain criteria are met. This program originates with the local banker.

Proper planning prior to contacting a financial institution can minimize the problem of adequate financing. Success in irrigation depends largely on your management ability. An indication of that ability can be expressed to your credit supplier in the form of farm records, profit and loss statements, net worth statements and cash flow statements. In addition to these records, you should be prepared to supply your credit agency with an estimation of the potential payback capacity of the irrigation investment. This is where the crop budgets and total enterprise analysis is very helpful.

Information on irrigation financing:

Contact irrigation dealers, other irrigators in the area, banks and other farm financial organizations.

The Ag Pace irrigation financing program through the Bank of North Dakota can be found online.

NDSU publication AE1674, "Funding Assistance Programs for Irrigation Development," is available at county Extension offices or online.

✓Step 6: Select and Manage Your Irrigated Crops

Crops selected for irrigation should produce an economic yield increase. This means the average yearly yield increase over dryland production must be great enough to pay for the investment in irrigation and increased production costs as well as some additional profit. Historically, irrigating corn (for silage or grain), alfalfa, sugar beets, potatoes and dry edible beans has been profitable for good irrigation managers.

Irrigation provides an environment conducive to increased plant production for long-season crops; however, it also provides a favorable environment for disease, insects and weeds. The irrigator must know how to manage the irrigation system and crop rotations to minimize potential problems. By scouting the field on a regular basis and using integrated pest management methods and best management practices, the irrigator should be able to manage the irrigation system profitably.

The irrigator must be aware of agronomic practices that favor irrigation and are crop-specific, such as proper hybrid selection, row widths, appropriate plant populations, higher fertilizer requirements and split applications of fertilizer to minimize leaching potential.

Irrigated crop water management is extremely important to prevent yield loss due to moisture stress, minimize pumping costs and prevent leaching of nutrients. A method of irrigation scheduling must be used. Soil moisture monitoring by the feel method commonly is used, but more accurate methods, such as the checkbook method, are available. Whichever method is used, it will require increased management skills and additional time. Irrigation scheduling is a daily process.

Information on irrigated crop production:

- Irrigation scheduling methods are available online.

- Irrigated crop research and variety trials are available in the annual reports from the Carrington, Oakes and Williston Research Extension Centers Variety Trials and Nesson Valley Irrigation Project.

Advance Planning

To make the transition from dryland to irrigated production a success, the equipment should be installed and operational prior to the growing season. Take time to decide on the system you want and allow time - several months - for delivery and setup. Give serious consideration to fall delivery of equipment so it can be assembled during the fall or winter and be operational prior to the cropping season. Attempts to rush the process may prove costly in capital outlay and development that may not fit your needs during the 30- to 35-year life of the system.

Irrigation Equipment Costs

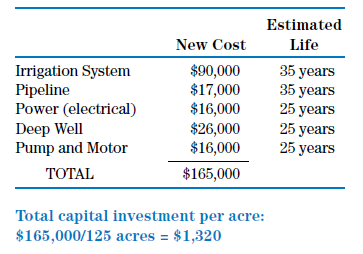

The following example of development costs is for a center pivot irrigation system covering 125 acres. One well about 100 feet deep with 20 feet of screen in the field corner nearest the road or power line is assumed to provide an adequate water supply of 800 gallons per minute for the system.

1. Irrigation System: $85,000 to $95,000 for a new quarter-section center pivot system (approximately 1,280 feet) with a concrete pivot pad and setup in the field. Included in this cost estimate are a check valve, flow meter, shut-off valve, pressure gauge and fittings, along with air and pressure relief valves.

2. Pipeline: A pipeline from the well to the pivot must be at least 8 inches in diameter to reduce friction loss and provide sufficient carrying capacity. For this example, the pipeline will be 1,600 feet. If the pipeline crosses hills or ridges, air relief valves must be located at the high points. If the low point of the pipeline is not at the pivot or well, a pump-out must be provided to remove water from the pipeline prior to winter. Pipe cost can vary significantly, so check with a local supplier.

3. Power and Control: $10,000 to $20,000 for electrical control panels, wire, electrician costs, etc. This does not include the cost to get power to the site by the power supplier. An electrical safety circuit must be connected between the well and the pivot control panel. This provides protection in case of pivot or pump failure.

a) Electric drive pivot – Electrical lines must be run from the local electric supplier to the control panel and then to the pivot. Three-phase power is preferable if available economically. An engine with a generator also can supply power.

b) Hydraulic drive pivot – An electric or engine-driven hydraulic pump is required.

4. Well Costs: $24,000 to $28,000. This includes test holes, production well site selection, drilling, testing and developing, screen and casing. Typical costs range from $250 to $300 per foot for a completed production well.

5. Pump and Motor: Costs depend on the flow rate, pumping water level, system pressure requirements, elevation differences and length of pipeline. Electric-powered pumps may be about $16,000; a comparable diesel-powered pump may cost about $20,000, which includes the right-angle gear head, fuel tank and other accouterments.

The following example calculates the total capital cost of a typical quarter-section center pivot irrigation system on a per-acre basis:

December 2018